A4 Mk2

| Replacing oil seal for pinion shaft |

| Special tools and workshop equipment required |

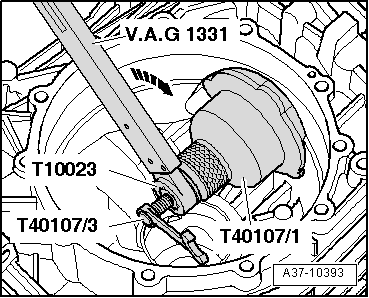

| t | Torque wrench -V.A.G 1331- |

| t | Insert tool -T10023- |

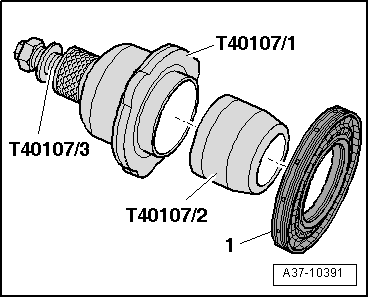

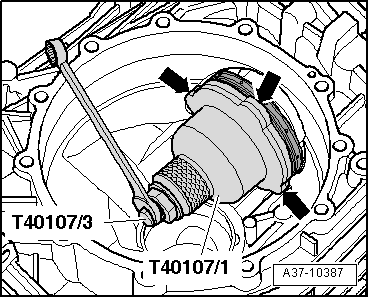

| t | Removal and assembly tool -T40107- |

| t | Assembly lever |

| t | Cleaning fluid -D 009 401 04- |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Caution

Caution