A4 Mk2

| Checking map-controlled engine cooling thermostat -F265- |

| Special tools and workshop equipment required |

| t | Hand-held multimeter -V.A.G 1526 B- |

| t | Auxiliary measuring set -V.A.G 1594 C- |

| t | CLIC hose clip pliers -V.A.G 1723- |

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

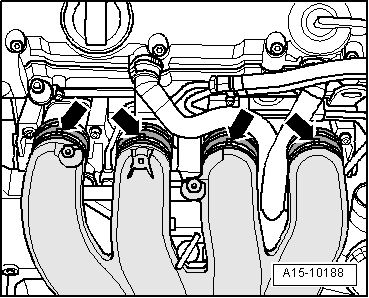

| Component | Nm |

| Intake manifold to bracket | 20 |

| Throttle valve module -J338- to intake manifold | 10 |