A4 Mk2

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

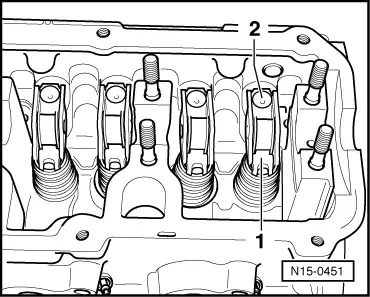

| Component | Nm |

| Retaining frame to cylinder head | 23 |

| Camshaft sprocket to camshaft | 100 |

WARNING

WARNING Caution

Caution