| –

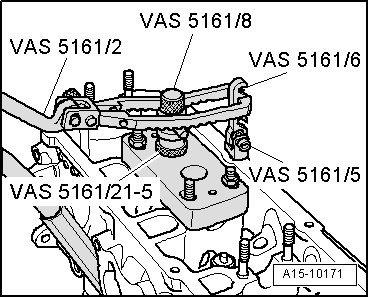

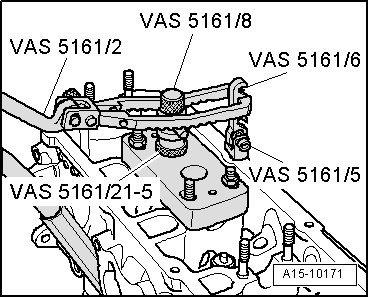

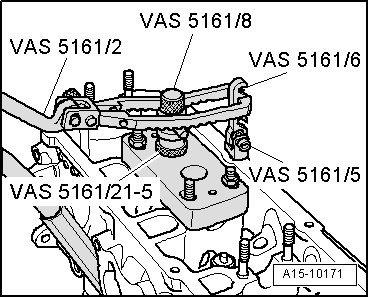

| Screw snap-in device -VAS 5161/6- with engaging fork -VAS 5161/5- into guide plate. |

| –

| Slide knurled spacer ring (height 8.4 mm) -VAS 5161/21-5- onto assembly cartridge -VAS 5161/8-. |

| –

| Attach pressure fork -VAS 5161/2- to snap-in device and push assembly cartridge down. |

| –

| At the same time, turn knurled screw of assembly cartridge clockwise until ends engage in valve cotters. |

| –

| Move knurled screw back and forth slightly; the valve cotters are thus forced apart and taken up by the cartridge. |

| –

| Release the pressure fork. |

| –

| Take out assembly cartridge with knurled spacer ring, valve head and valve spring. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note