| –

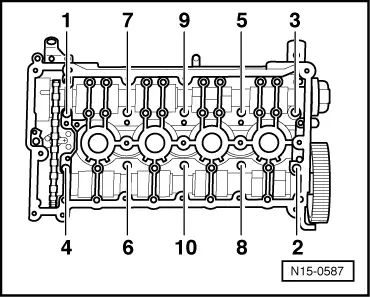

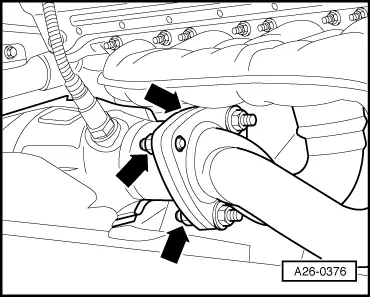

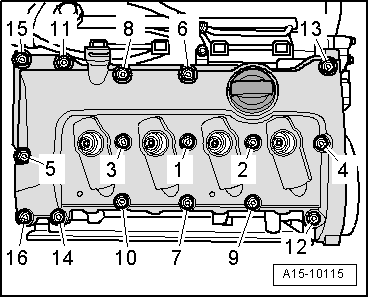

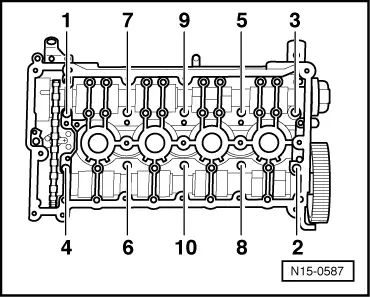

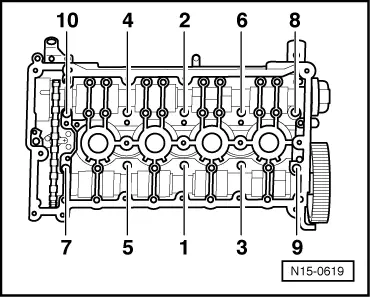

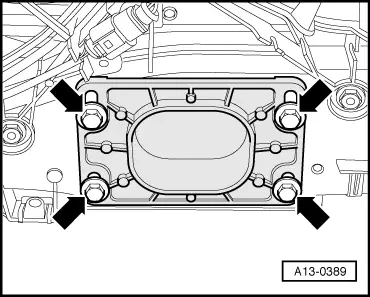

| Remove cylinder head bolts in the sequence: -1 ... 10-. |

| –

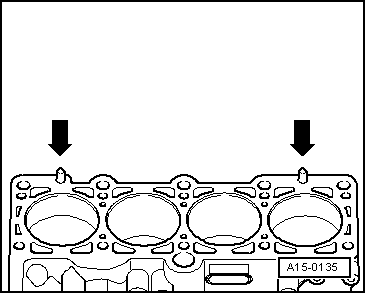

| Remove the cylinder head with the assistance of a 2nd mechanic. |

Note | t

| Cylinder heads which have cracks between the valve seats or between a valve seat insert and the spark plug thread can be re-installed without reducing service life, provided the cracks are only slight and do not exceed a maximum of 0.3 mm in width, and no more than the first 4 turns of the spark plug threads are cracked. |

| t

| Renew the cylinder head bolts. |

| t

| Renew self-locking nuts and bolts when performing assembly work. |

| t

| Renew bolts which are tightened to a specified angle as well as oil seals and gaskets. |

| t

| Carefully remove any sealant residue from the cylinder head and cylinder block. Ensure that no long scores or scratches are made on the surfaces. |

| t

| Carefully remove any remaining emery and abrasive material. |

| t

| No oil or coolant must be allowed to remain in the blind holes for the cylinder head bolts in the cylinder block. |

| t

| When installing an exchange cylinder head with the camshafts fitted, the contact surfaces between bucket tappet and cam running surface must be oiled after installation of the cylinder head. |

| t

| The plastic protectors fitted to protect the open valves must only be removed immediately before fitting the cylinder head. |

| t

| Do not remove new cylinder head gasket from packaging until it is ready to be fitted. |

| t

| Handle gasket very carefully. Damage to the silicone coating or the indented area will lead to leaks. |

| t

| When fitting a new cylinder head or cylinder head gasket, drain off all the old coolant and refill with new coolant. |

| t

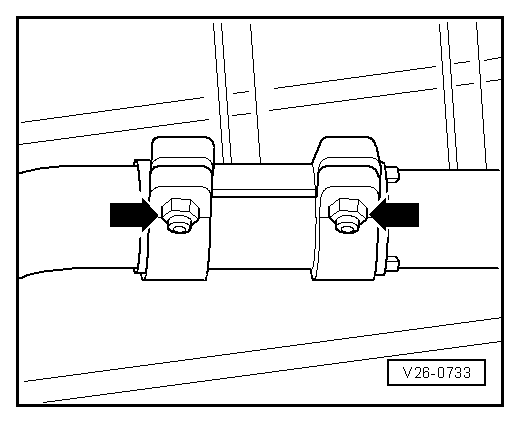

| Secure all hose connections with the correct type of hose clips (same as original equipment) → Parts catalogue. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Caution

Caution