| –

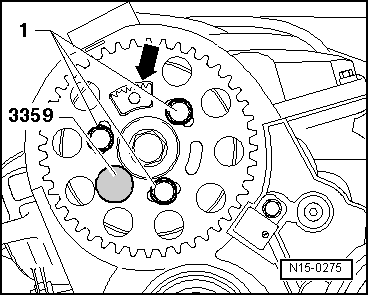

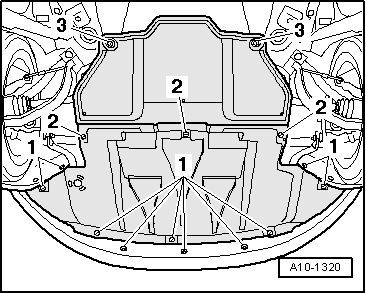

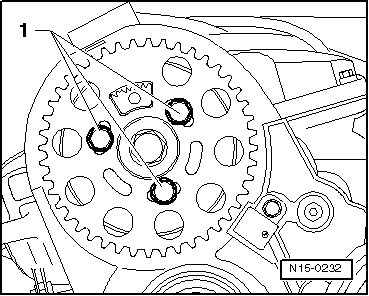

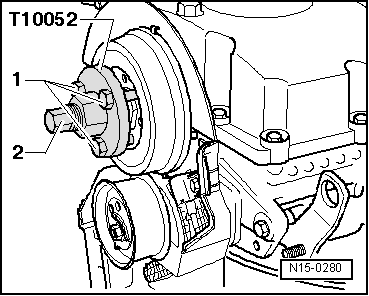

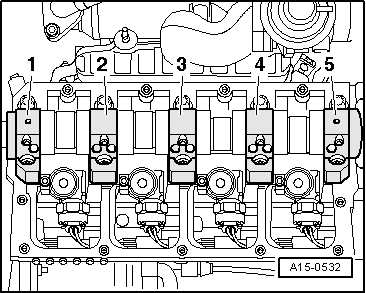

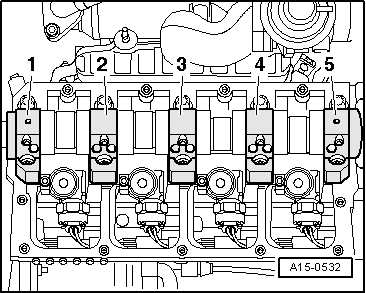

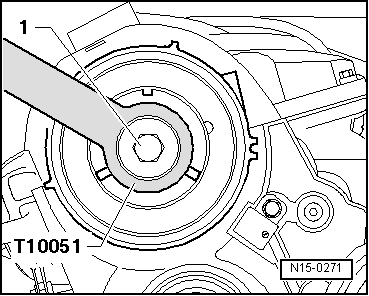

| Push camshaft sprocket onto hub. |

| l

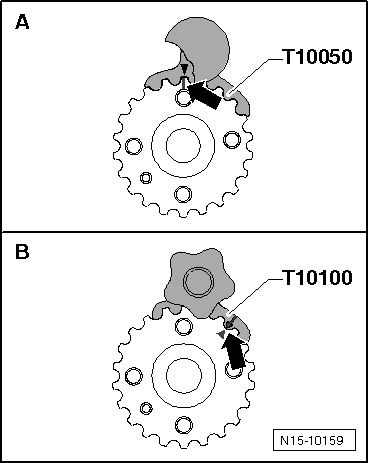

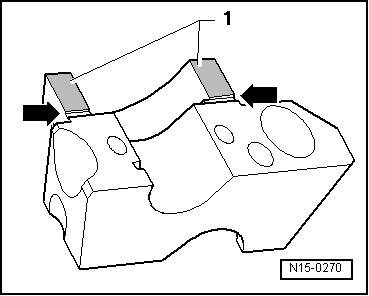

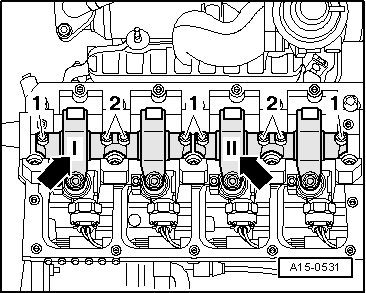

| Toothed segment -arrow- of camshaft sprocket must be at top. |

| –

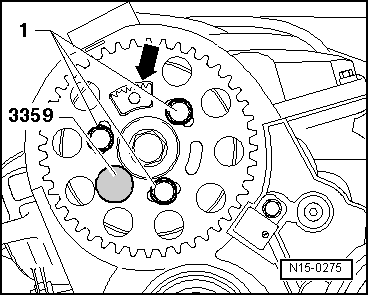

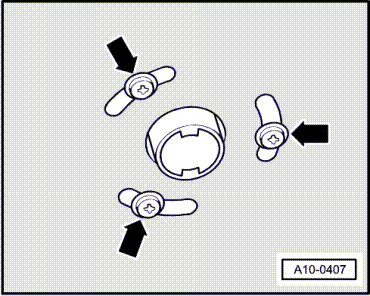

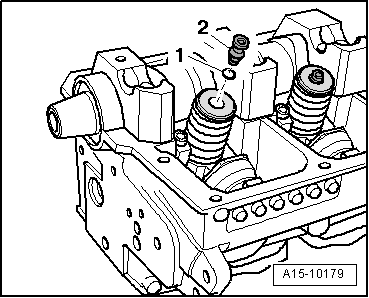

| Screw in bolts -1- finger-tight. |

| –

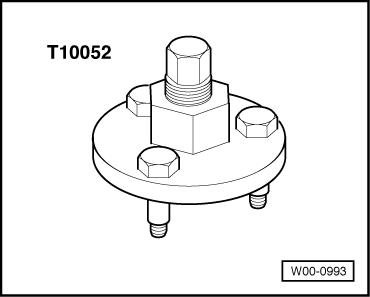

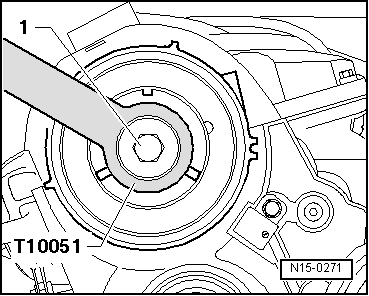

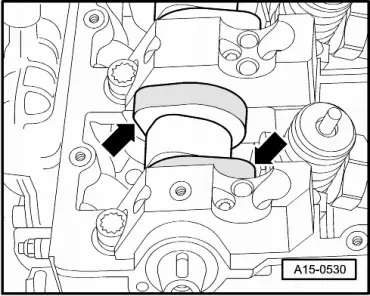

| Lock hub with locking pin -3359-. |

| The remaining installation steps are carried out in the reverse sequence. |

| –

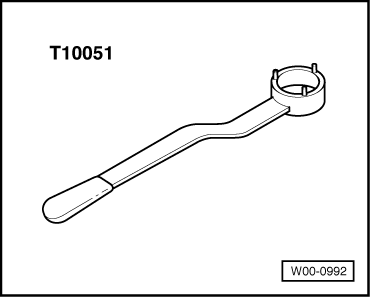

| Fit toothed belt (adjust valve timing): |

| t

| Vehicles with hydraulically damped tensioning roller - engine codes AVB, AVF, AWX → Anchor. |

| t

| Vehicles with friction-damped tensioning roller - engine codes AVB, AVF, AWX → Anchor. |

| t

| Engine codes BKE, BPW, BRB, BRC → Anchor. |

| –

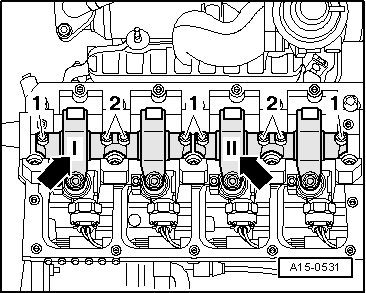

| If the rocker arm shafts or ball studs and adjuster screws were renewed, the unit injectors must be adjusted → Rep. Gr.23. |

Note | t

| After installing the camshaft, the engine must NOT be started for about 30 minutes. The hydraulic tappets have to settle (otherwise valves will strike pistons). |

| t

| After working on the valve gear, turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note