| –

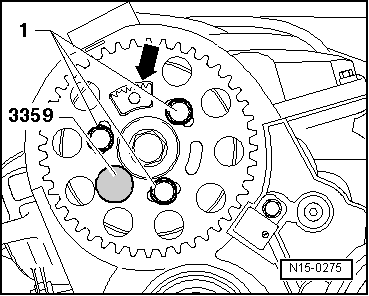

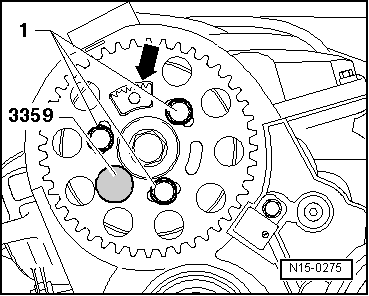

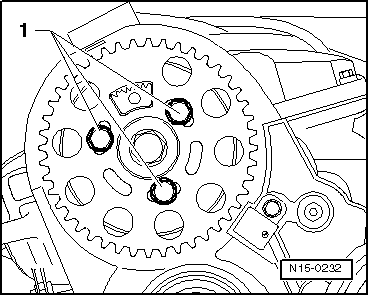

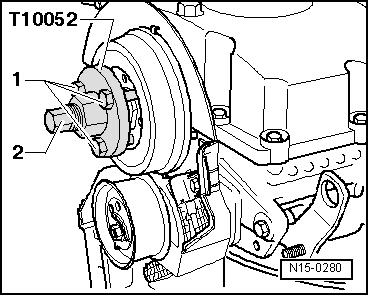

| Push camshaft sprocket onto hub. |

| l

| Toothed segment -arrow- of camshaft sprocket must be at top. |

| –

| Screw in bolts -1- finger-tight. |

| –

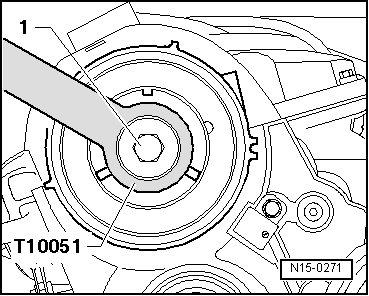

| Lock hub with locking pin -3359-. |

| The remaining installation steps are carried out in the reverse sequence. |

| –

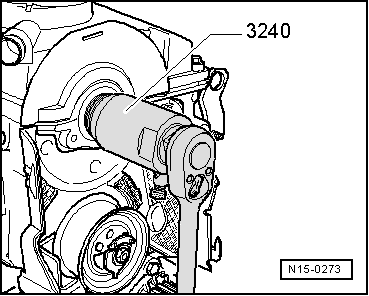

| Fit toothed belt (adjust valve timing): |

| t

| Vehicles with hydraulically damped tensioning roller - engine codes AVB, AVF, AWX → Anchor. |

| t

| Vehicles with friction-damped tensioning roller - engine codes AVB, AVF, AWX → Anchor. |

| t

| Engine codes BKE, BPW, BRB, BRC → Anchor. |

| –

| Install poly V-belt: vehicles up to 05.2003 → Anchor, vehicles from 06.2003 onwards → Anchor. |

|

|

|

Note

Note

Note

Note