| –

| Renew centre bolt for toothed belt sprocket. |

| l

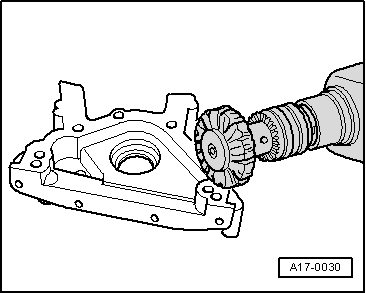

| Contact surface between toothed belt sprocket and crankshaft must be free of oil. |

| l

| Do not lubricate bolt for crankshaft sprocket. |

| –

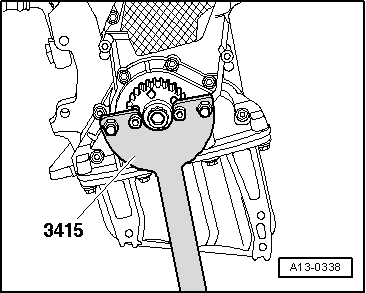

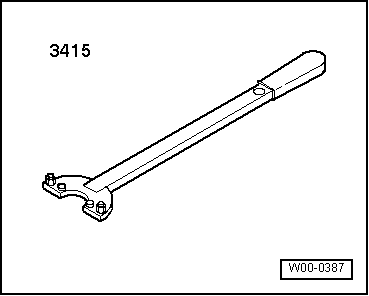

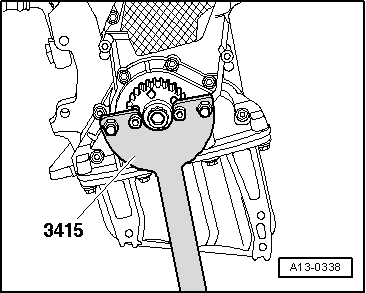

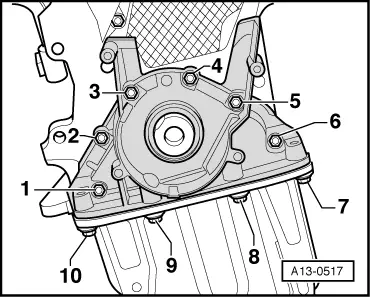

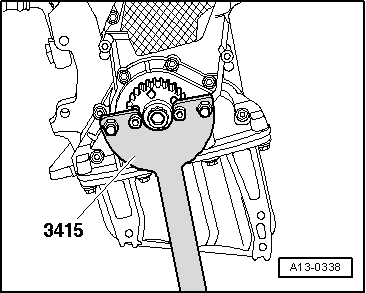

| Install crankshaft sprocket. To do this, counterhold sprocket with counterhold tool -3415-. |

| The remaining installation steps are carried out in the reverse sequence. |

| –

| Fit toothed belt (adjust valve timing): |

| t

| Vehicles with hydraulically damped tensioning roller - engine codes AVB, AVF, AWX → Anchor. |

| t

| Vehicles with friction-damped tensioning roller - engine codes AVB, AVF, AWX → Anchor. |

| –

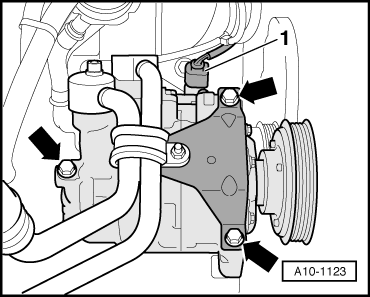

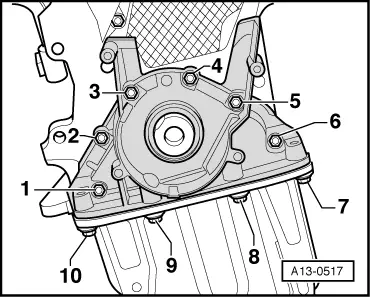

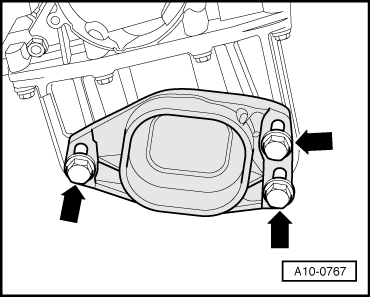

| Install bracket for air conditioner compressor → Item |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING