| –

| Renew centre bolt for toothed belt sprocket. |

| l

| Contact surface between toothed belt sprocket and crankshaft must be free of oil. |

| l

| Do not lubricate bolt for crankshaft sprocket. |

| –

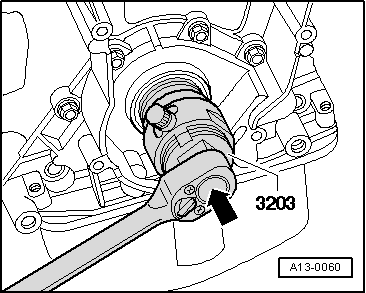

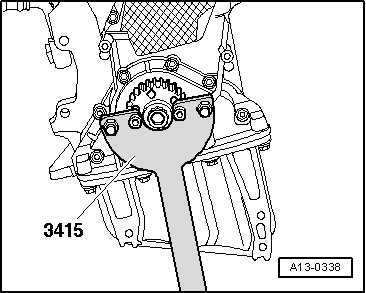

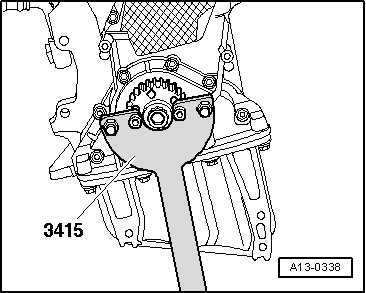

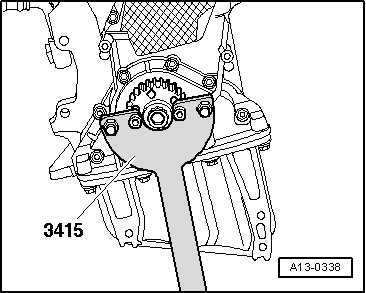

| Install crankshaft sprocket. To do this, counterhold sprocket with counterhold tool -3415-. |

| The remaining installation steps are carried out in the reverse sequence. |

| –

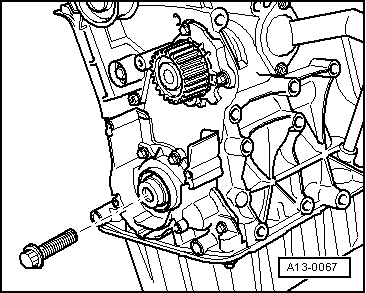

| Fit toothed belt (adjust valve timing): |

| t

| Vehicles with hydraulically damped tensioning roller - engine codes AVB, AVF, AWX → Anchor. |

| t

| Vehicles with friction-damped tensioning roller - engine codes AVB, AVF, AWX → Anchor. |

| t

| Engine codes BKE, BPW, BRB, BRC → Anchor. |

| –

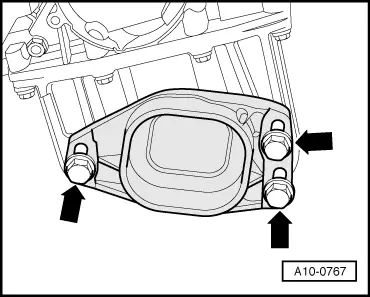

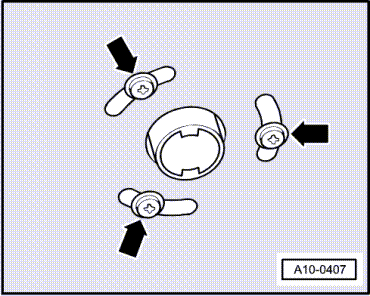

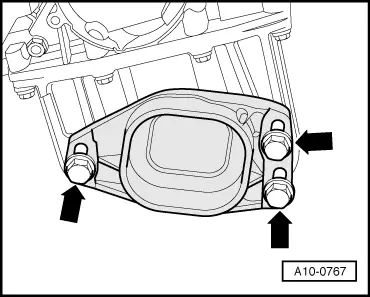

| Install vibration damper: vehicles up to 05.2003 → Anchor, vehicles from 06.2003 onwards → Anchor. |

| –

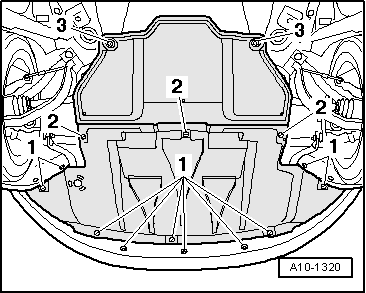

| Install poly V-belt: vehicles up to 05.2003 → Anchor, vehicles from 06.2003 onwards → Anchor. |

|

|

|

Note

Note