| t

| Engine and gearbox support -VAS 6095- |

| t

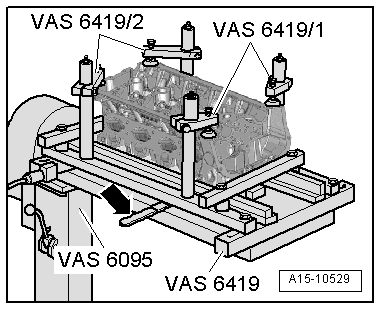

| Cylinder head tensioning device -VAS 6419- |

| Handling ceramic glow plugs: |

| The Audi A4 with 4-cylinder 2.0 ltr. 4-valve TDI engine with particulate filter is equipped exclusively with NGK ceramic glow plugs. |

Note | NGK ceramic glow plugs are colour-coded with a white, or possibly “silver-coloured” seal. |

Caution | Important: Always observe the special instructions for handling ceramic glow plugs. |

|

Caution | t

| Due to the special properties of the material used, ceramic glow plugs are easily damaged and require extra care when handling and removing/installing. Always observe the special instructions when removing and installing ceramic glow plugs → Rep. Gr.28. |

| t

| Transport and store only in original packaging or packed separately in bubble wrap. |

| t

| Do not remove new ceramic glow plugs from packaging until they are ready to be fitted. |

| t

| Ceramic glow plugs are sensitive to knocks and bending. For this reason, ceramic glow plugs which have been dropped (even from a height of only about 2 cm) must not be installed, even if no damage is apparent (hair-line cracks may not be visible). |

| t

| Always install a new ceramic glow plug if you are not sure the old one is in perfect condition. |

| t

| Damaged glow plugs (e.g. heater pin of the glow plug is damaged) will invariably cause engine damage. |

| t

| If the heater pin of the glow plug is damaged, the fragments must be removed from the combustion chamber before starting the engine for the first time, otherwise this will invariably cause mechanical damage (piston seizure). |

|

|

|

|

Note

Note

Note

Note

Note

Note

Caution

Caution