A4 Mk2

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

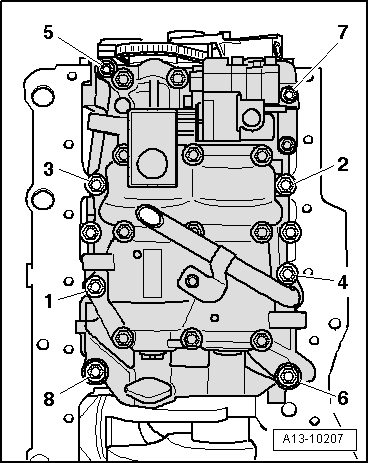

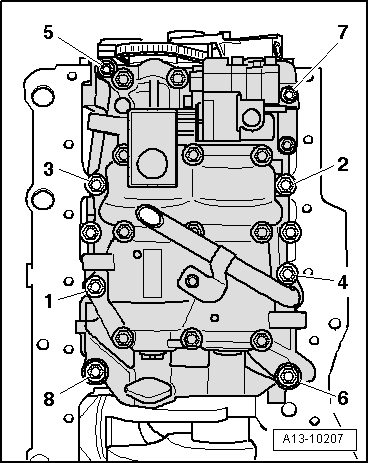

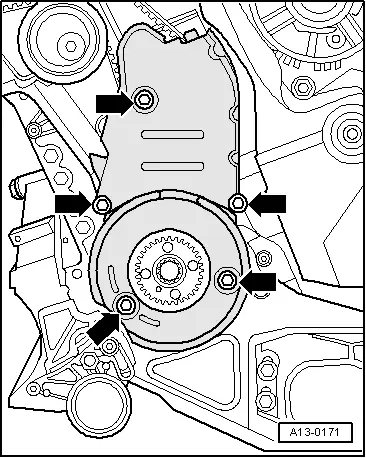

| Component | Nm | ||||||||

| Balance shaft assembly | M7 | 13 + 90° 1)2) | |||||||

| to cylinder block | M8 | 20 + 90° 1)2) | |||||||

| Chain tensioner to balance shaft assembly | 9 | ||||||||

| Chain sprocket to balance shaft | 10 + 90° 1)2) | ||||||||

| Cover for | Chain tensioner | 5 3) | |||||||

| chain sprocket to: | Oil pump | 5 3) | |||||||

| Toothed belt cover to engine | 10 3) | ||||||||

| |||||||||