A4 Mk2

| Cylinder head - exploded view of components |

Note

Note| t | Never set down cylinder head on workbench, as this could damage injectors and glow plugs. |

| t | A pressure limiting valve (for lubrication points in cylinder head) is screwed into each cylinder head. Tightening torque: 25 Nm. |

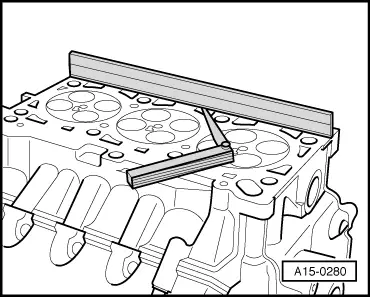

| 1 - | Cylinder head |

| q | Removing: left-side → Chapter; right-side → Chapter |

| q | Checking for distortion → Fig. |

| q | Cylinder heads must not be machined on diesel engines |

| q | Installing → Chapter |

| q | If renewed, refill system with fresh coolant |

| 2 - | Gasket for cylinder head cover |

| q | Renew if damaged or leaking |

| q | Before fitting gasket apply sealant at sealing points → Chapter „Removing and installing cylinder head cover (left-side)“, → Chapter „Removing and installing cylinder head cover (right-side)“ |

| 3 - | Cylinder head bolt |

| q | Renew |

| q | Note sequence when loosening: cylinder head (left-side) → Anchor, cylinder head (right-side) → Anchor |

| q | Note correct sequence when tightening → Anchor |

| 4 - | Cylinder head cover |

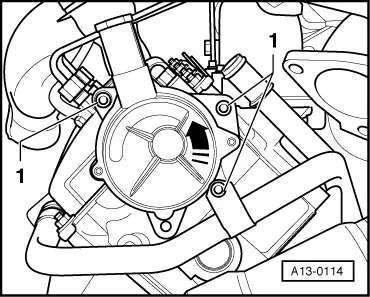

| q | Removing and installing: left-side → Chapter, right-side → Chapter |

| q | Renew cylinder head cover if injector seals are damaged |

| 5 - | Deflector ring |

| q | Renew if damaged |

| 6 - | Seal |

| q | Renew if damaged or leaking |

| 7 - | Filler cap |

| 8 - | Injector pipes |

| q | Use ring spanner -3035- for removal |

| q | Always remove pipework complete |

| q | Do not alter shape |

| q | Tighten to 30 Nm |

| 9 - | Return pipe |

| 10 - | Seal |

| q | Renew |

| 11 - | Banjo bolt, 5 Nm |

| 12 - | Intake manifold |

| q | Removing and installing → Rep. Gr.23 |

| 13 - | 10 Nm |

| q | Tighten in stages and in diagonal sequence |

| 14 - | Gasket |

| q | Renew |

| 15 - | Dowel sleeve |

| q | 2x |

| q | Take care to prevent dowel sleeves dropping into intake ports |

| 16 - | 10 Nm |

| q | Tighten in stages and in diagonal sequence |

| 17 - | Heat shield for exhauster pump |

| q | Depending on version |

| 18 - | 10 Nm |

| 19 - | Exhauster pump |

| q | For brake servo |

| q | Removing and installing → Fig. |

| 20 - | O-rings |

| q | For exhauster pump |

| q | Renew |

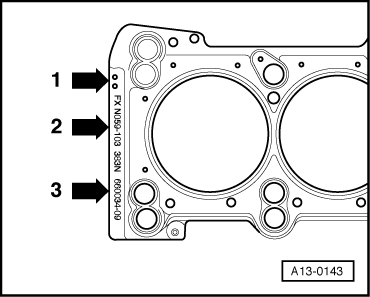

| 21 - | Cylinder head gasket |

| q | Different thicknesses |

| q | Note marking → Fig. |

| q | Renewing → Chapter |

| q | Installation position: Part No. towards cylinder head |

| q | If renewed, refill system with fresh coolant |

|

|

Note

Note

|

|

|

|