A4 Mk2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

| Component | Nm | |

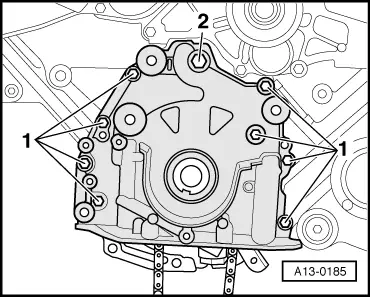

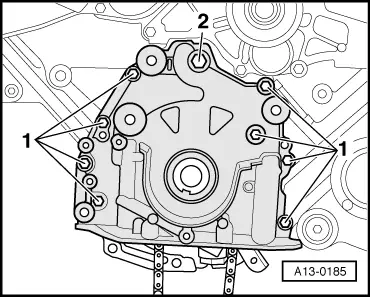

| Front sealing flange to cylinder block | M6 | 10 |

| M8 | 30 | |

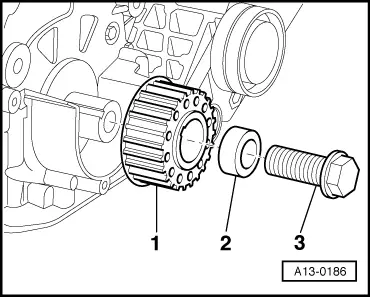

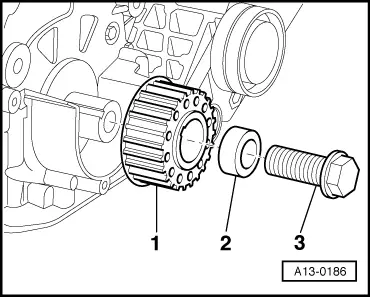

| Toothed belt sprocket to crankshaft | 200 + 180° → Note → Note | |

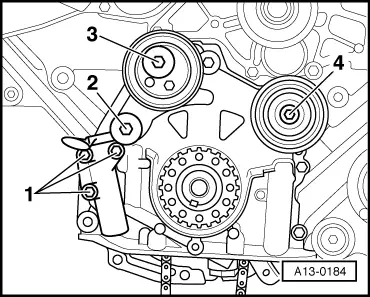

| Toothed belt tensioning roller to sealing flange (front) | 42 | |

| Tensioner to sealing flange (front) | 10 | |

| Tensioning lever to sealing flange (front) | 42 | |

| Idler roller to sealing flange (front) | 45 | |

|

Caution

Caution