A4 Mk2

| Removing and installing camshafts |

| Special tools and workshop equipment required |

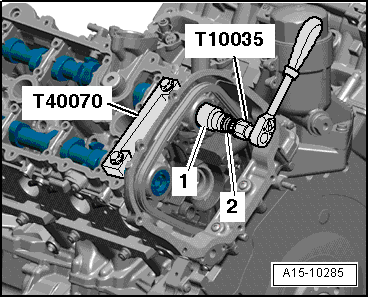

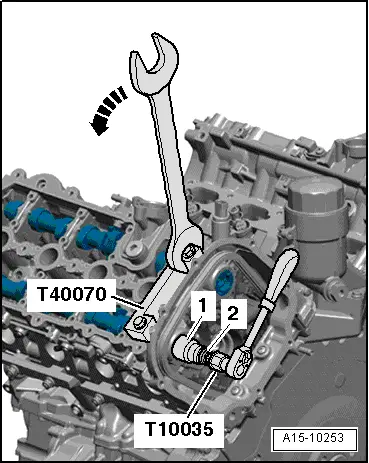

| t | Special wrench -T10035- |

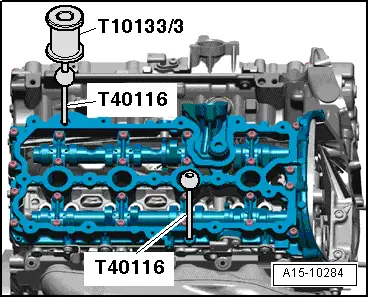

| t | Puller -T10133/3- |

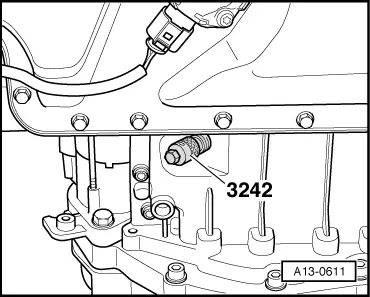

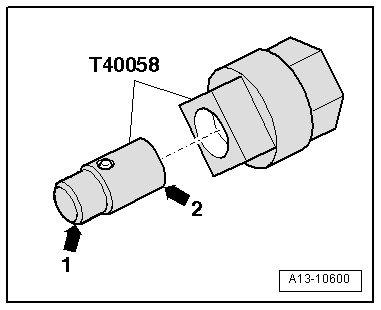

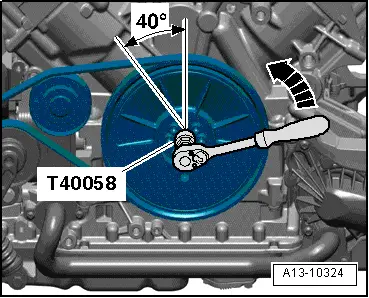

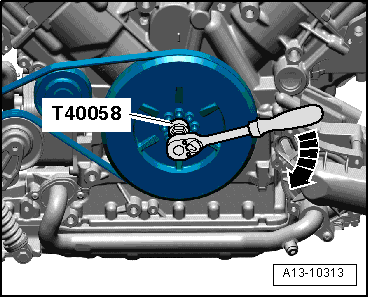

| t | Adapter -T40058- |

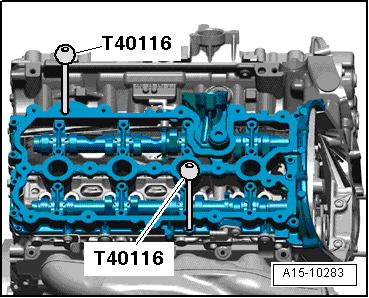

| t | Locating pins for retaining frame -T40116- |

| t | Electric drill with plastic brush attachment |

| t | Safety goggles |

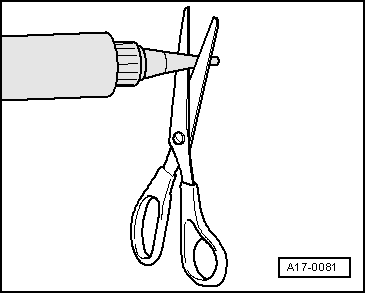

| t | Sealant → Electronic parts catalogue |

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

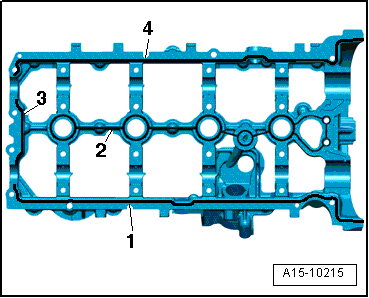

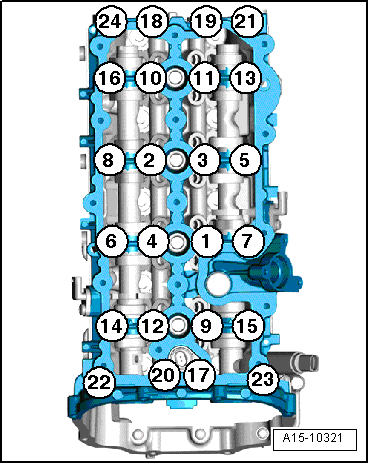

| Component | Nm |

| Retaining frame to cylinder head | 8 |

Caution

Caution WARNING

WARNING