| –

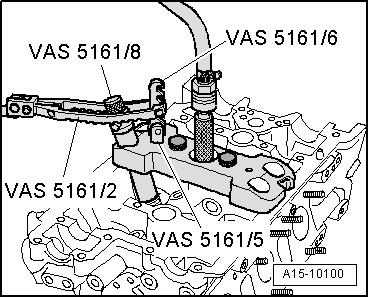

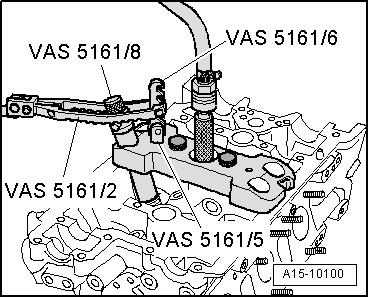

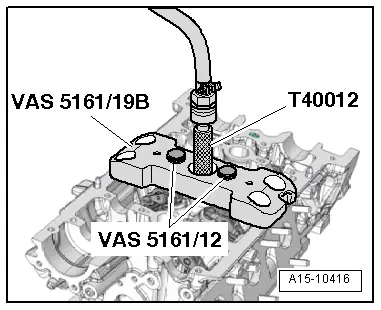

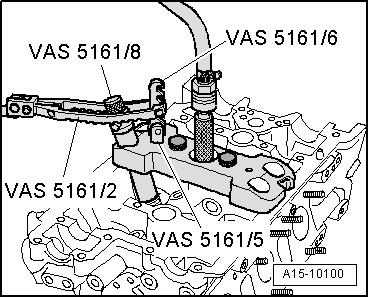

| Screw snap-in device -VAS 5161/6- with engaging fork -VAS 5161/5- into guide plate. |

| –

| Insert assembly cartridge -VAS 5161/8- into guide plate. |

| –

| Attach pressure fork -VAS 5161/2- to snap-in device and push assembly cartridge down. |

| –

| At the same time, turn knurled screw of assembly cartridge clockwise until tips engage in valve cotters. |

| –

| Move knurled screw back and forth slightly; the valve cotters are thus forced apart and taken up by the assembly cartridge. |

| –

| Release the pressure fork. |

| –

| Remove assembly cartridge. |

| –

| Detach guide plate and turn to one side. |

| l

| The compressed air hose remains connected. |

| –

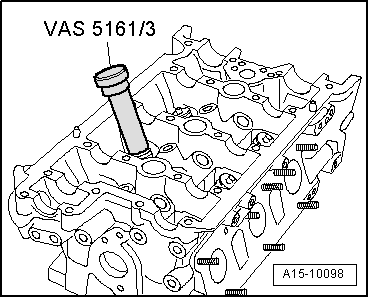

| Remove valve spring with valve spring plate. |

|

|

|

Note

Note

Note

Note