A4 Mk2

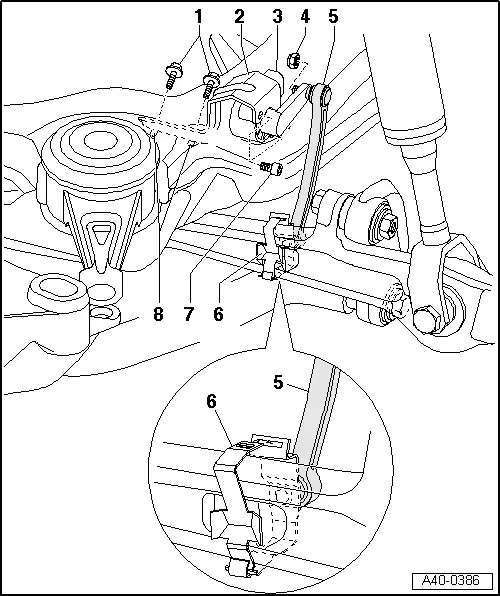

| Exploded view of components |

| 1 - | Hexagon bolt |

| q | 9 Nm |

| 2 - | Bracket |

| 3 - | Front left vehicle level sender -G78- |

| q | Is tested electrically via self-diagnosis |

| q | If malfunctions occur, follow “Guided Fault Finding” procedure using vehicle diagnostic, testing and information system -VAS 5051A- |

| q | Removing and installing → Anchor |

| 4 - | Self-locking nut |

| q | 10 Nm |

| q | Always renew if removed |

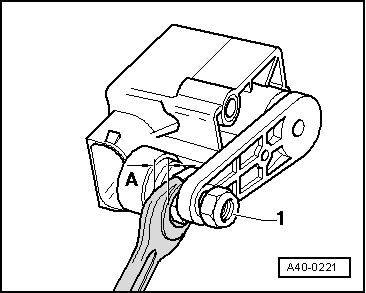

| 5 - | Coupling rod from front left vehicle level sender -G78- |

| q | Do not pull coupling rod off ball joint on vehicle level sender -G78- |

| 6 - | Retaining clip |

| q | Fastener of clip must face upwards at track control link and towards rear of vehicle |

| 7 - | Hexagon socket head bolt |

| q | 4 Nm |

| 8 - | Pop rivet nut |

|

|

|

Note

Note

|

|

Note

Note

|

|