A4 Mk2

| Removing and installing wheel bearing unit (bolted version) |

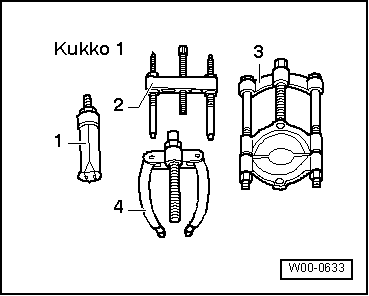

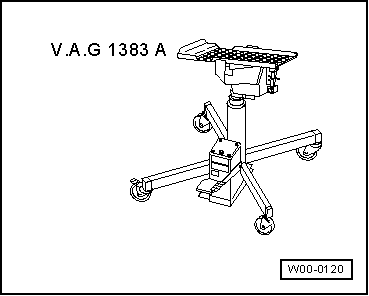

| Special tools and workshop equipment required |

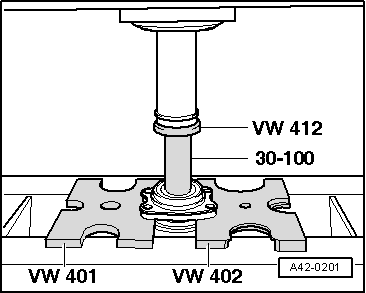

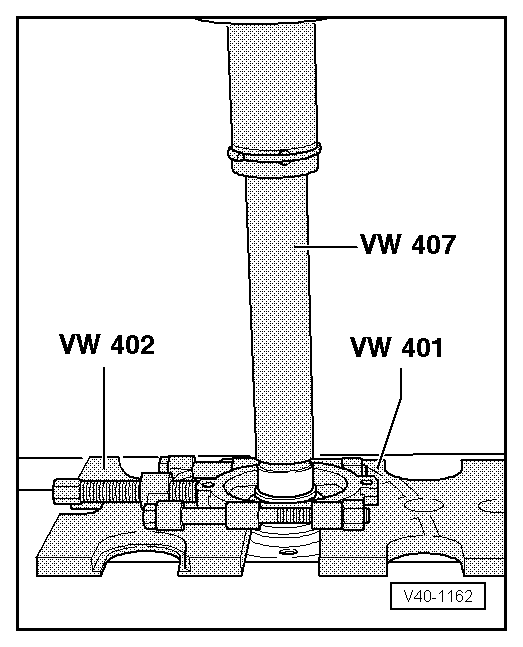

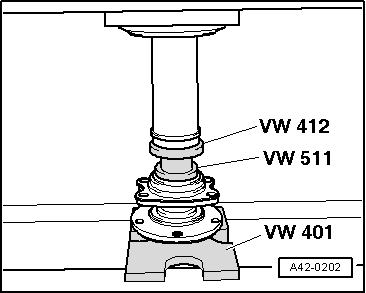

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Tube -VW 416 B- |

| t | Press tool -VW 412- |

| t | Press tool -VW 407- |

| t | Tube -VW 519- |

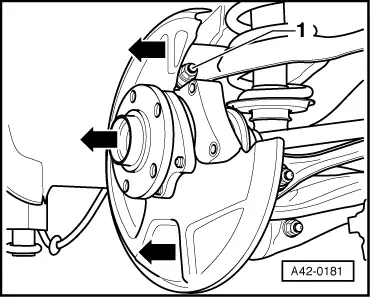

| 1 - | Wheel bearing housing |

| q | Removing and installing wheel bearing housing → Chapter |

| 2 - | Wheel bearing |

| 3 - | Wheel hub |

| q | Removing and installing → Chapter |

| 4 - | Flange bolt |

| q | Always renew |

| q | 200 Nm + 180° |

| q | Tighten to 200 Nm while vehicle is raised; turn through specified angle only when vehicle is standing on its wheels |

| q | Do not loosen more than 90° when vehicle is standing on its wheels |

| 5 - | Drive shaft |

| q | Removing and installing → Chapter |

| q | Servicing (with 100 mm Ø inner joint) → Chapter |

| q | Servicing (with 108 mm Ø inner joint) → Chapter |

| 6 - | Washer |

| 7 - | Self-locking nut |

| q | Always renew |

| 8 - | Shock absorber |

| q | Removing and installing → Chapter |

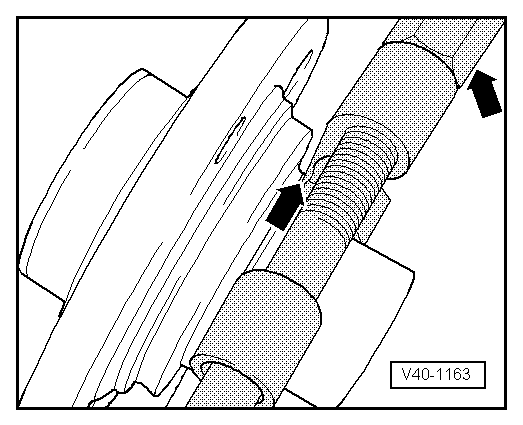

| q | Note correct installation position → Fig. |

| q | Note different running gear versions; see vehicle data sticker → Anchor |

| q | Defective shock absorbers must always be degassed and drained before disposal → Chapter |

| q | Checking shock absorber following removal → Chapter |

| 9 - | Bolt with washer |

| q | 36 Nm |

| 10 - | Hexagon socket head bolt |

| q | 10 Nm |

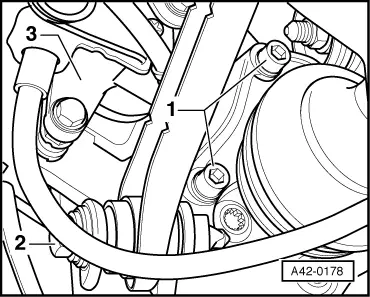

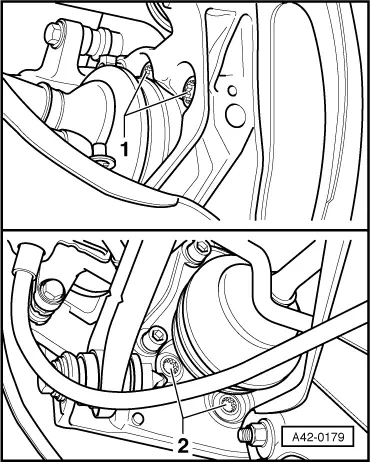

| 11 - | Speed sensor |

| q | Routing of wiring → Fig., → Fig. |

| 12 - | Countersunk bolts (4x) |

| q | 80 Nm + 90° |

| q | Always renew |

| 13 - | Bolt with washer |

| q | 150 Nm + 90° |

| q | Always renew |

| q | Suspension must be in unladen position when tightening bolt connections |

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

| Tightening torques: | |

| Drive shaft to hub (M14); use new bolt | 115 Nm + 180° |

| Drive shaft to hub (M16); use new bolt | 200 Nm + 180° |

| Drive shaft to drive flange (M8) | 40 Nm |

| Drive shaft to drive flange (M10) | 70 Nm |

| Brake caliper to hub carrier | 70 Nm + 90° |

| Wheel bearing unit to hub carrier | 80 Nm + 90° |