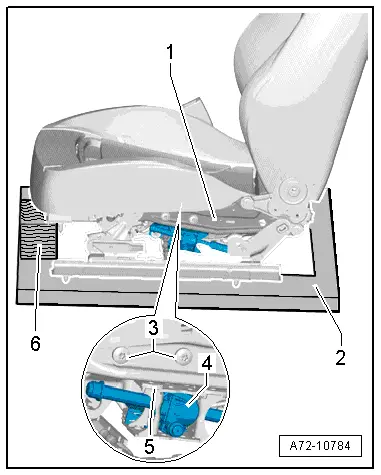

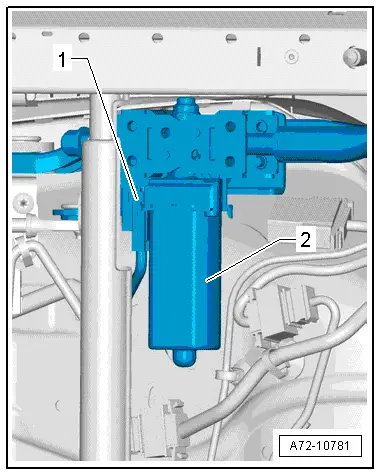

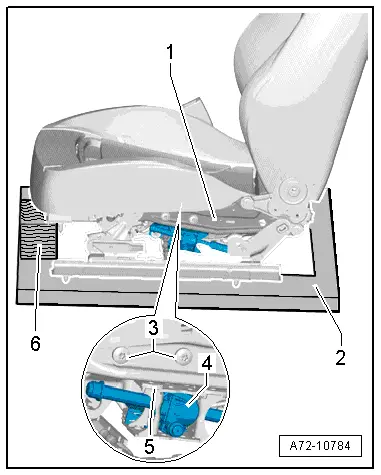

Caution | If strain on bolt connection adjustment spindle/seat pan is not relieved when unscrewing or bolting on, threaded hole in seat pan will be damaged or destroyed. |

|

| –

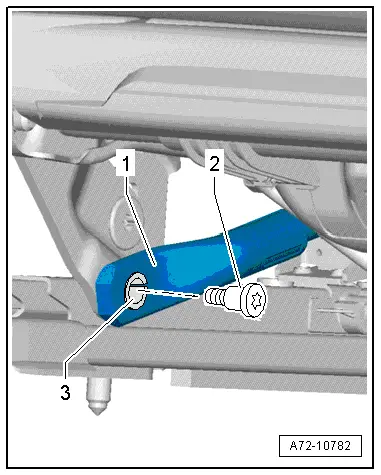

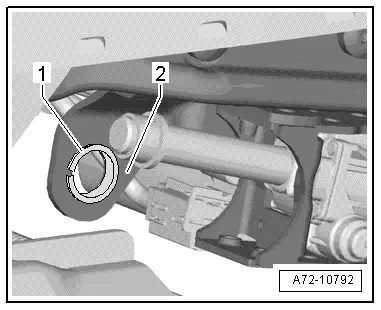

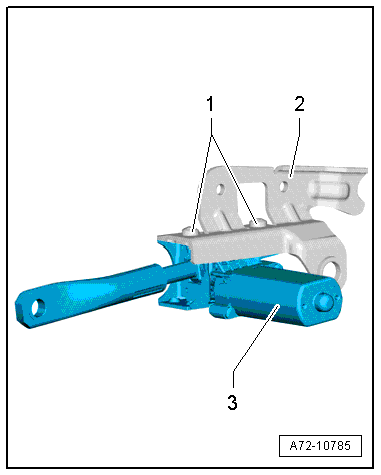

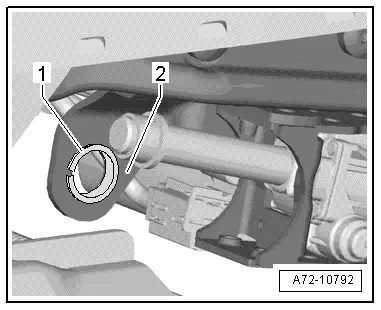

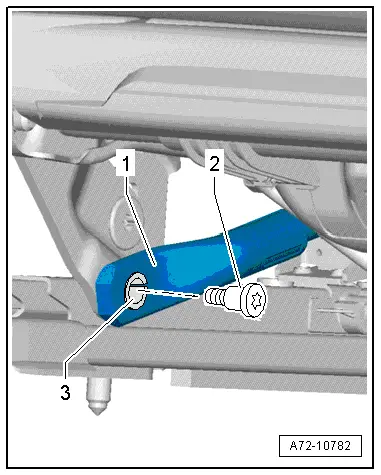

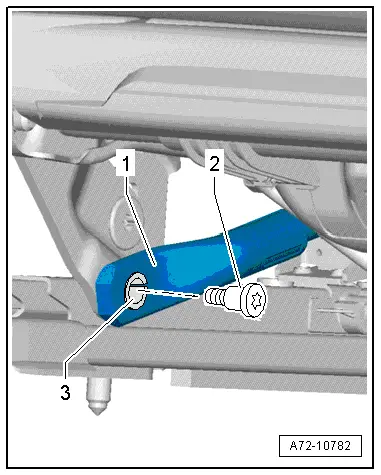

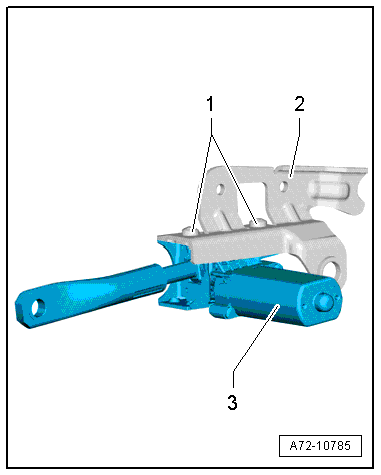

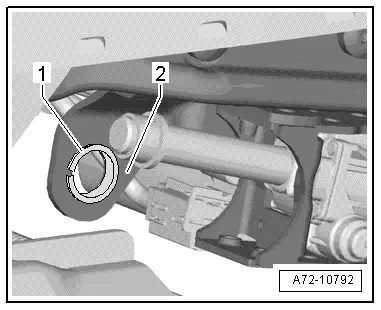

| Take care not to damage bush -3- when inserting bolt -2-. |

Caution | t

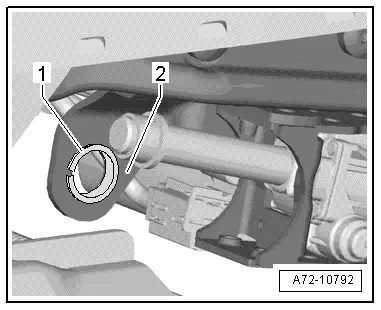

| The bushes cannot be renewed with the equipment available to workshops. |

| t

| The corresponding components must be renewed if the bushes are damaged. |

|

| Perform remaining installation steps in reverse order of removal; observe the following: |

Note | Make sure electrical connectors are fitted correctly (as far as stop) and engage audibly. |

WARNING | The battery must be connected with the ignition switched on. If pyrotechnic components (e.g. airbag or belt tensioner) are inexpertly repaired, this may result in unwanted triggering after connecting the battery. There must not be anyone in the vehicle while you are connecting the battery. |

|

Note | If the airbag warning lamp -K75- indicates a fault following installation, you must interrogate, erase and then re-interrogate the event memory → Vehicle diagnostic tester. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note