A4 Mk3

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

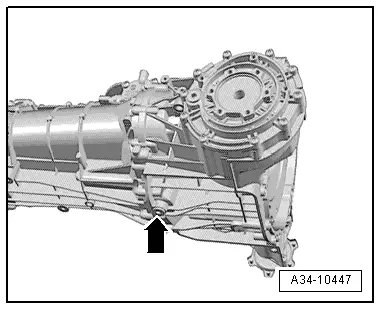

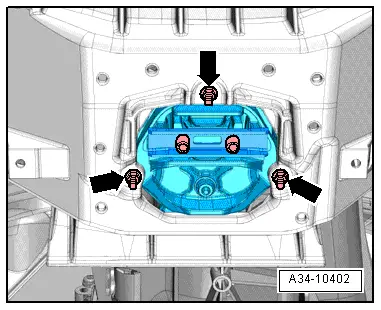

| Component | Nm | |

| Heat shield for propshaft to centre differential housing | 25 | |

WARNING

WARNING Caution

Caution