| t

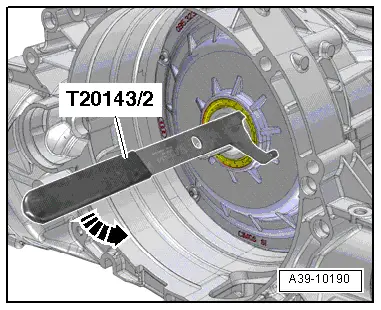

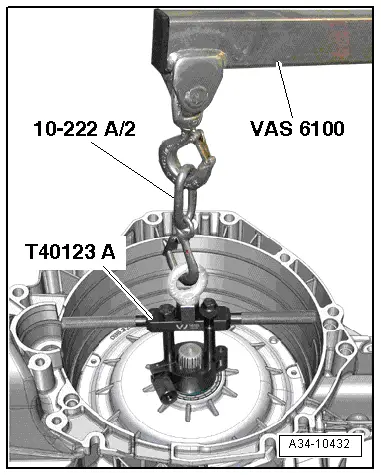

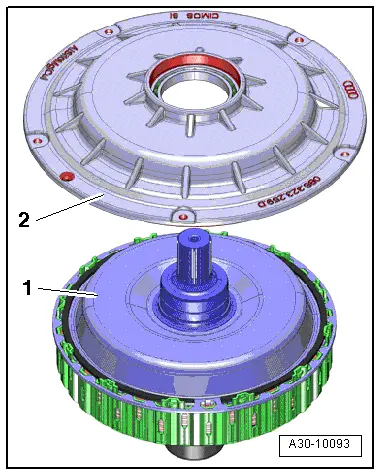

| If the clutch cover cannot be detached, knock lightly on the input shaft with a plastic hammer while a second mechanic lifts the clutch cover by hand. |

| t

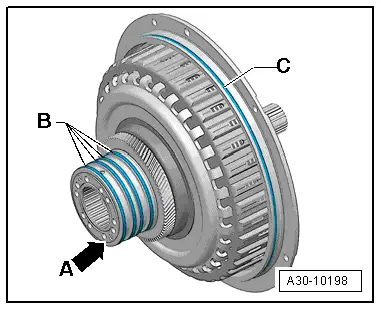

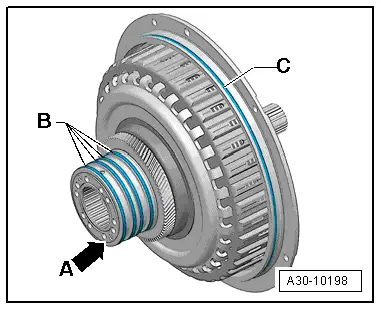

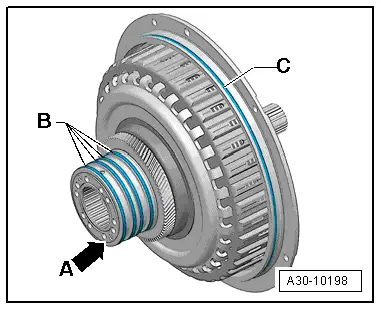

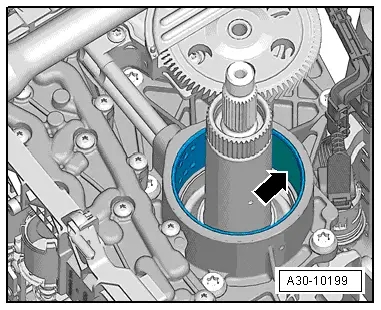

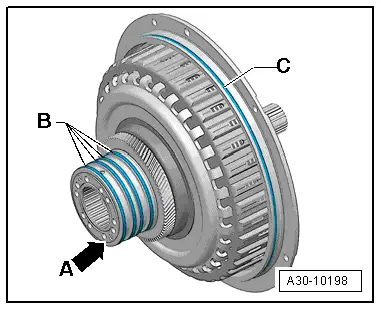

| Take care not to damage the thin collar -arrow A-. |

| Installation is carried out in reverse sequence; note the following: |

Note | Renew O-ring and circlip. |

| –

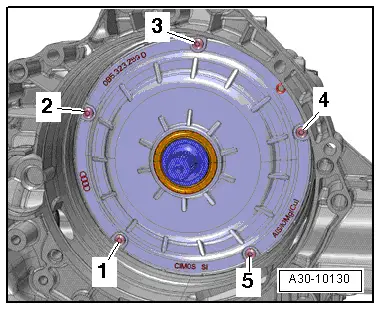

| Clean sealing surface on clutch cover. |

| –

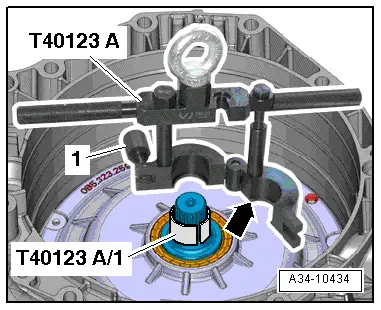

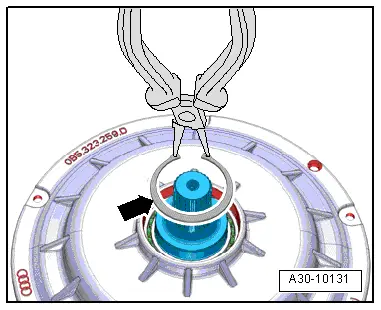

| Turn rectangular section seals -B- on hub and check for freedom of movement and axial play. |

Note | If any of the rectangular section seals do not move freely, the dual clutch must not be fitted. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution