| Removing rear final drive |

| Refer to general repair instructions → Chapter. |

| –

| Place vehicle on lifting platform. |

| De-energising high-voltage system |

WARNING |

| The high-voltage system must be de-energised according to the Guided Fault Finding routine in the ⇒ vehicle diagnostic tester, and ONLY by this method. |

DANGER! | High voltage can cause fatal injury. |

| Danger of severe or fatal injuries from electric shock. |

| t

| Voltage levels in the high-voltage system constitute a safety hazard. |

| t

| For reasons of safety, persons with life-preserving or other electronic medical devices in or on their body must not perform any work on the high-voltage system. Such medical devices include internal analgesic pumps, implanted defibrillators, pacemakers, insulin pumps and hearing aids. |

| t

| The high-voltage system may only be de-energised by a suitably qualified person (Audi high-voltage technician). |

| t

| It must be definitely confirmed that the high-voltage system is de-energised. The system may only be de-energised using the vehicle diagnostic tester via „Guided Fault Finding“. |

| t

| The qualified person (Audi high-voltage technician) confirms that the system is de-energised and ensures that it cannot be re-energised by storing the ignition key and the maintenance connector for high-voltage system - TW - in a safe place. |

| t

| The qualified person (Audi high-voltage technician) marks the vehicle by attaching the appropriate warning signs. |

|

Note | t

| De-energising high-voltage system: |

| t

| Connect vehicle diagnostic tester. |

| t

| Select Guided Fault Finding mode. |

| t

| Using the GoTo button, select the following menu options in succession. |

| t

| Function/Component Selection |

| t

| Self-diagnosis-compatible systems |

| t

| 8C - Hybrid battery management -J840 |

| t

| 8C - Hybrid battery management, functions |

| t

| 51 - De-energise high-voltage system (Rep. Gr. 93) |

| –

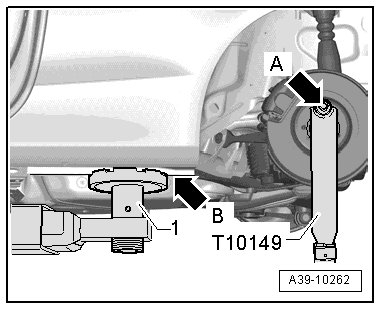

| Detach wheel trim from rear left wheel (on vehicles with light alloy wheels, pull off trim cap using puller from vehicle tool kit). |

| –

| Remove rear left wheel. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING