A4 Mk3

| Dismantling and assembling hydraulic control unit |

| 1 - | Bolt |

| q | 5 Nm |

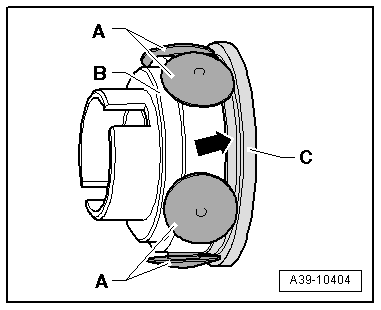

| 2 - | Four-wheel drive pump -V415- |

| q | Removing and installing → Chapter |

| 3 - | O-ring |

| q | Always renew |

| 4 - | Adapter |

Note

Note| t | Adapter can fall out during removal of four-wheel drive pump -V415- |

| t | Before installing four-wheel drive pump -V415-, insert adapter in recesses in hydraulic pump |

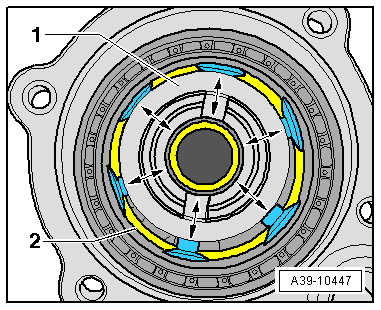

| 5 - | Hydraulic pump |

| q | Consists of guide ring, housing and 6 pistons |

| q | Assembling → Fig. |

| 6 - | Ball bearing |

| q | Can be removed and installed by hand |

| 7 - | Pipe (left-side) |

| q | Tighten nuts to 30 Nm |

| q | Installed between hydraulic control unit and superposition gear (left-side) |

| q | When installing, first screw in both nuts hand-tight |

| 8 - | O-ring |

| q | Always renew |

| 9 - | Oil pressure and oil temperature sender -G437- |

| q | 10 Nm |

| q | Brown connection |

| q | Removing and installing → Chapter |

| 10 - | Oil pressure and oil temperature sender 2 -G640- |

| q | 10 Nm |

| q | Black connection |

| q | Removing and installing → Chapter |

| 11 - | Clutch valve 2 for four-wheel drive -N446- |

| q | Colour: brown |

| q | Removing and installing → Chapter |

| q | Installation position: connector must face upwards towards oil pressure and oil temperature sender |

Caution

Caution

|

| 12 - | Clutch valve for four-wheel drive -N445- |

| q | Colour: black |

| q | Removing and installing → Chapter |

| q | Installation position: connector must face upwards towards oil pressure and oil temperature sender |

Caution

Caution

|

| 13 - | Bolt |

| q | 2.5 Nm |

| 14 - | O-ring |

| q | Always renew |

| q | Fit on clutch valve |

| 15 - | Spring |

| q | Insert in guide → Item |

| 16 - | Guide |

| q | Installation position: large diameter must face ball → Item |

| 17 - | Ball |

| q | Before installing, insert in guide → Item |

| 18 - | Housing for hydraulic control unit |

| q | With centring pins -arrows- |

| q | Centring pins lock hydraulic control unit with gasket on final drive housing |

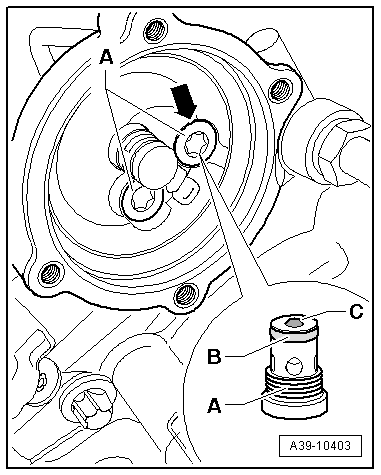

| 19 - | Ball |

| q | Before installing, insert in hole in shuttle valve → Item |

| 20 - | O-ring |

| q | Always renew |

| 21 - | Shuttle valve |

| q | 8 Nm |

| q | Removing and installing → Fig. |

| 22 - | Gasket |

| q | With strainer |

| q | Position on centring pins of housing for hydraulic control unit |

| 23 - | Pipe (right-side) |

| q | Tighten nuts to 30 Nm |

| q | Installed between hydraulic control unit and superposition gear (right-side) |

| q | When installing, first screw in both nuts hand-tight |

|

|

|

|

Note

Note

|

|