| –

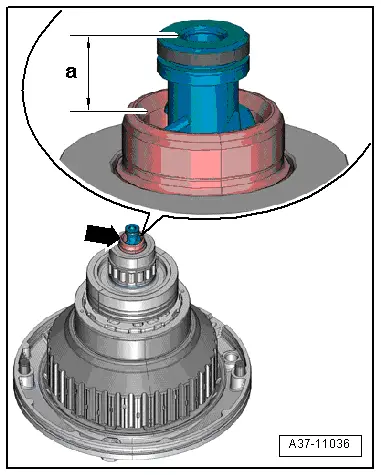

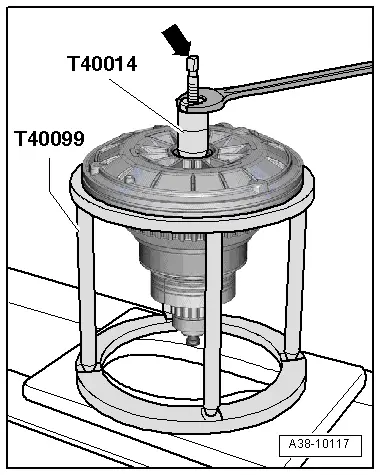

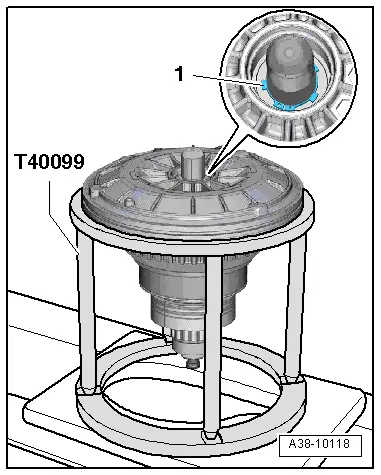

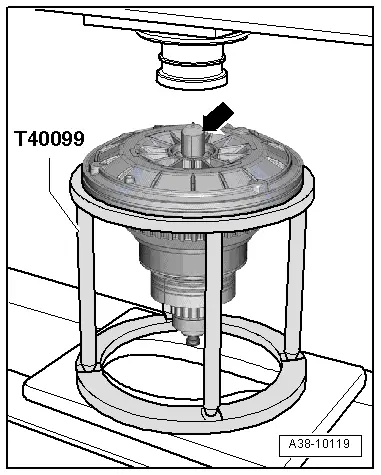

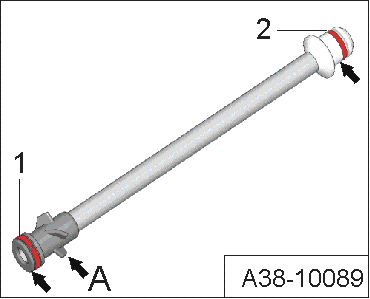

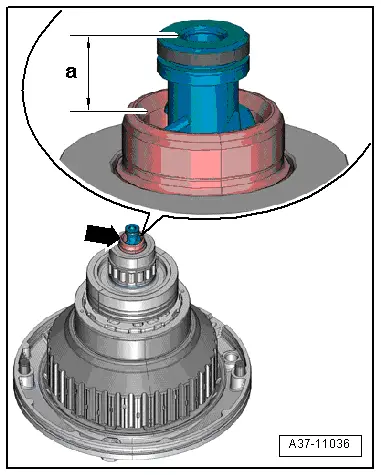

| Press oil pipe -arrow- down into input shaft as far as stop. |

| l

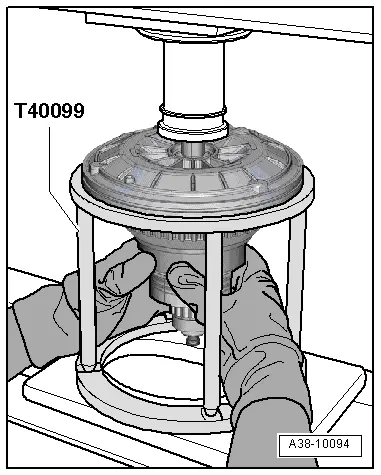

| With oil pipe fully inserted, distance -a- from end of oil pipe to input shaft should be approx. 11.5 mm. |

Note | t

| If the distance is less, the oil pipe may be damaged (the end could have broken off if the oil pipe was pushed in too far). |

| t

| If the distance is larger, the oil pipe is not pushed in far enough. |

Caution | A damaged oil pipe will cause problems when driving off from a standstill or complete gearbox failure. |

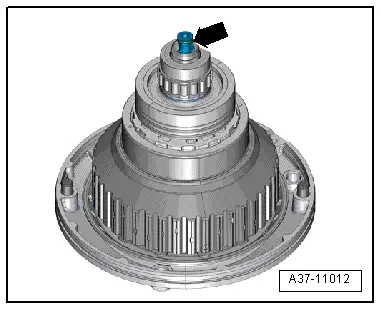

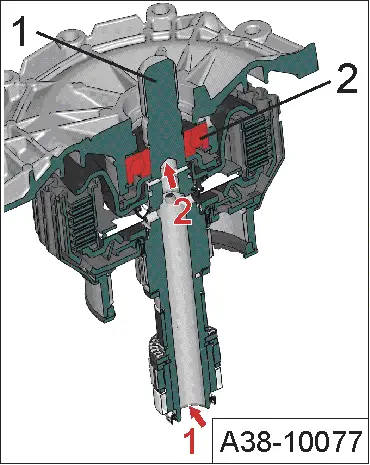

| The input shaft must not be laid down on the projecting oil pipe -arrow-. |

|

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

WARNING

WARNING Caution

Caution