| –

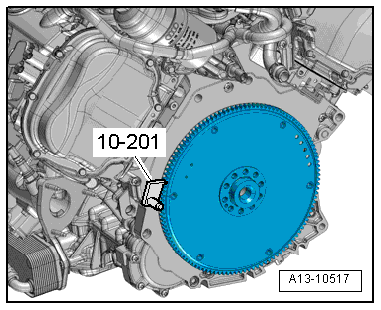

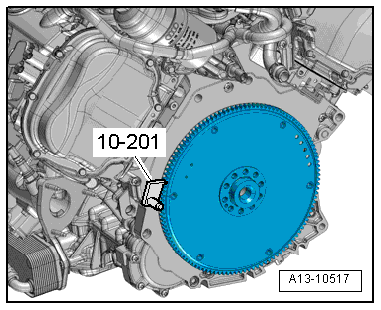

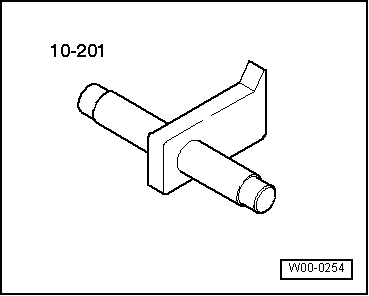

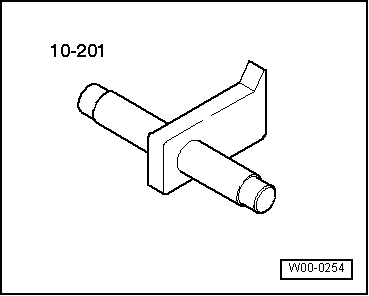

| Insert counterhold tool -10 - 201- to slacken bolts. |

Caution | Take care not to damage outer surface of bearing flange on drive plate. |

| Use a multi-point socket bit with a length of at least 40 mm to slacken and tighten the drive plate bolts. |

|

| –

| Remove bolts and take off drive plate and sender wheel. |

| Installation is carried out in the reverse order; note the following: |

Note | t

| Renew bolts for drive plate. |

| t

| On vehicles with manual gearbox or multitronic gearbox 0AW, a needle bearing is fitted in the drive plate. On vehicles with automatic gearbox 0B6, no needle bearing should be fitted. Before installing, check that the needle bearing is fitted. Removing and installing needle bearing in drive plate (pressing in and out) → Chapter. |

| –

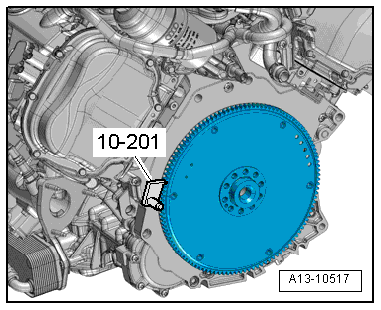

| Pay attention to dowel pin when installing drive plate. |

| –

| Fit counterhold tool -10 - 201- the other way round to tighten bolts. |

|

|

|

Note

Note

Note

Note