A4 Mk3

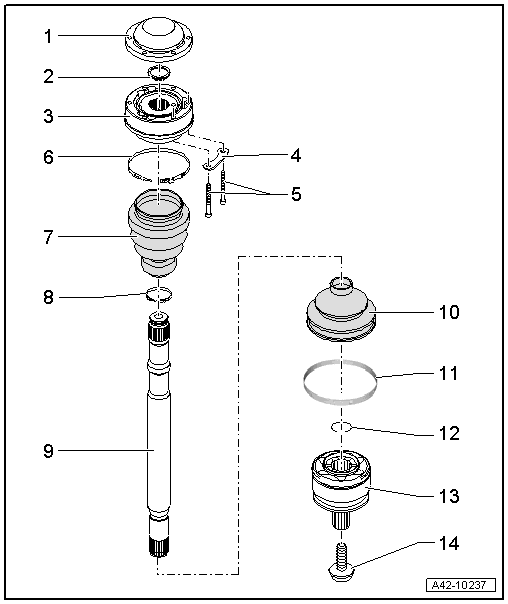

| Exploded view of drive shaft with 100 mm dia. outer constant velocity joint and 108 mm dia. inner sliding constant velocity joint |

| 1 - | Cover |

| q | Drive off cover carefully with drift |

| q | Always renew |

| q | Sealing surfaces between cover and inner CV joint must be free from grease on assembly |

| q | Before attaching to constant velocity joint, apply sealant to sealing surface → Anchor |

| 2 - | Circlip |

| q | Use normal commercial circlip pliers when removing and installing |

| q | Always renew |

| 3 - | Inner sliding constant velocity joint |

| q | Outside diameter: 108 mm |

| q | Renew only as complete unit |

| q | Checking → Chapter |

| q | Pressing off → Chapter |

| q | Pressing on → Anchor |

| q | Grease quantity and type → Anchor |

| q | Adhesive surfaces must be free of oil and grease |

| q | Grease splines on drive shaft lightly with grease used in joint when fitting joint onto drive shaft |

| 4 - | Lock plate |

| 5 - | Bolt |

| q | 70 Nm |

| q | Always renew if removed |

| 6 - | Hose clip |

| q | Always renew |

| q | Tightening → Anchor |

| 7 - | Boot for inner sliding constant velocity joint |

| q | Without vent hole |

| q | Check inner constant velocity joint if boot is damaged → Chapter |

| q | Sealing surfaces between boot and drive shaft must be free from grease on assembly |

| q | Briefly lift boot to equalise pressure before tightening hose clip |

| 8 - | Hose clip |

| q | Always renew |

| q | Tightening → Anchor |

| 9 - | Drive shaft |

| q | Removing and installing → Chapter |

| 10 - | Boot for outer constant velocity joint |

| q | Without vent hole |

| q | Check for splits and chafing, renew if necessary |

| q | Check outer constant velocity joint if boot is damaged → Chapter |

| q | Sealing surfaces between boot and outer CV joint must be free from grease on assembly |

| q | Briefly lift boot to equalise pressure before tightening hose clip |

| 11 - | Hose clip |

| q | Unfastening → Anchor |

| q | Tightening → Anchor |

| 12 - | Circlip |

| q | Always renew |

| q | For correct version refer to → Electronic parts catalogue |

| q | Fit into annular groove on shaft before installing (no longer visible once joint is installed) |

| q | Before fitting constant velocity joint, align circlip centrally with opening facing upwards. |

| 13 - | Outer constant velocity joint |

| q | Outside diameter: 100 mm |

| q | Renew only as complete unit |

| q | Checking → Chapter |

| q | Driving off → Chapter |

| q | Installing: drive onto shaft with plastic hammer until compressed circlip seats |

| q | Circlip must fit in chamfer on joint when installing; guide with pliers if necessary |

| q | Grease quantity and type → |

| q | Sealing surfaces between boot and outer CV joint must be free from grease on assembly |

| q | Grease splines on drive shaft lightly with grease used in joint when fitting joint onto drive shaft |

| 14 - | Bolt |

| q | Always renew |

| q | Observe instructions for loosening and tightening → Chapter |

| q | 200 Nm +180° |

Note

Note

|

| Grease quantity | of which in: | ||

| Outer joint | Total quantity | Joint | Boot |

| [mm] | [g] | [g] | [g] |

| 100 | 120 | 70 | 50 |

| Inner joint | Put in grease through ball bearing races | ||

| 108 | 120 | ||