| General repair instructions |

| Proper tools and the maximum possible care and cleanliness are essential for satisfactory repairs to the transmission units. The usual basic safety precautions also naturally apply when carrying out repair work. |

| A number of generally applicable instructions for the various repair procedures - which were previously repeated at numerous places in the Workshop Manual - are summarised here. They apply to the work described in this Manual. |

| t

| When installing a new gearbox, check the oil level and fill up with oil if necessary → Chapter. |

| t

| Thoroughly clean all joints and connections and the surrounding areas before dismantling. |

| t

| When installing gearbox ensure dowel sleeves are correctly seated. |

| t

| Thoroughly clean housing contact surfaces before applying sealing paste. |

| t

| Apply sealing paste -AMV 188 001 02- evenly and not too thickly. |

| t

| Breather holes must remain free of sealing paste. |

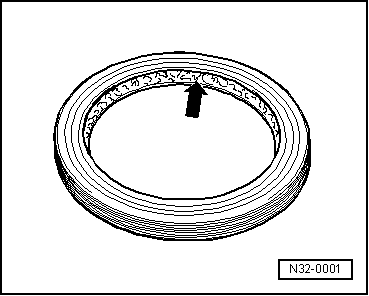

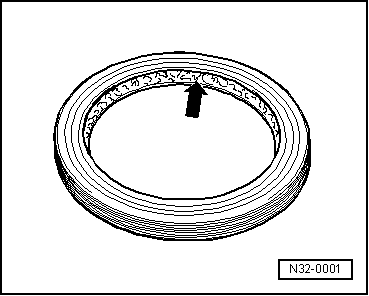

| O-rings, seals, oil seals and gaskets |

| t

| Always renew O-rings, seals and gaskets. |

| t

| After removing gaskets and seals, always inspect the contact surface on the housing or shaft for burrs resulting from removal or for other signs of damage. |

| t

| Thoroughly clean housing joint surfaces before assembling. |

|

|

|