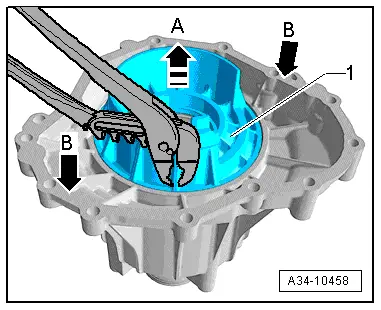

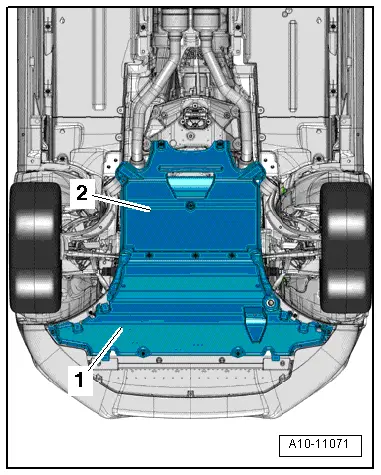

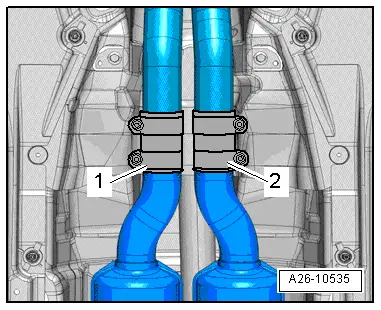

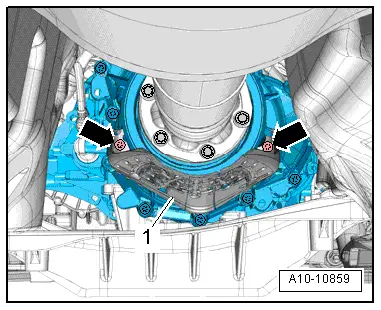

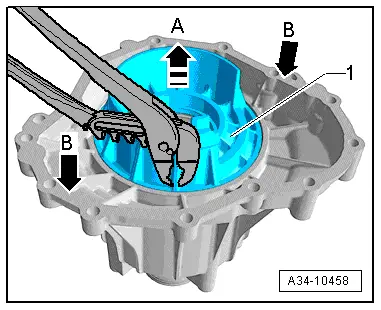

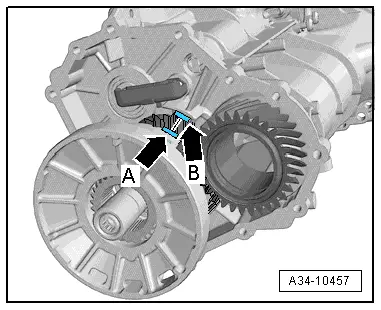

| If bearing plate -1- remains behind in centre differential housing, proceed as follows: |

Caution | Risk of damage to the sealing surface of the centre differential housing. |

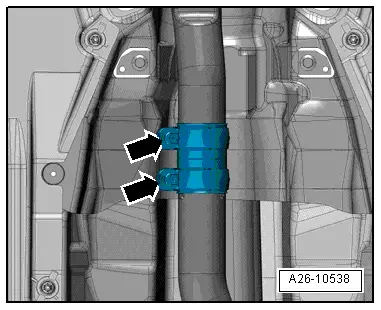

| Carefully tap the housing in several places with a hammer. |

|

| –

| Grip one of the side ribs on bearing plate -1- with pliers and pull off in direction of -arrow A-. |

| –

| While doing so, carefully tap alternate sides of housing -arrows B- with a rubber-headed hammer. |

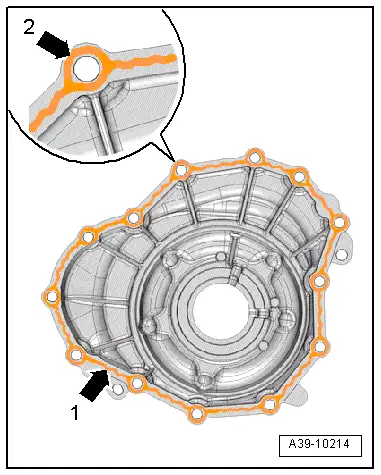

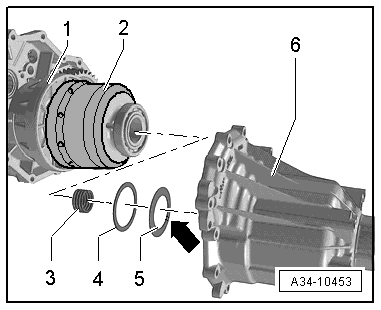

| Installation is carried out in reverse sequence; note the following: |

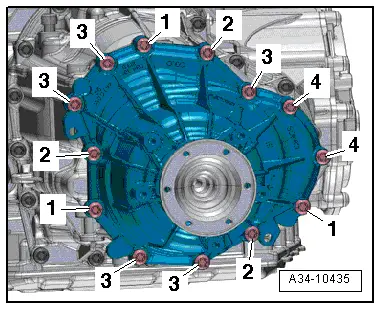

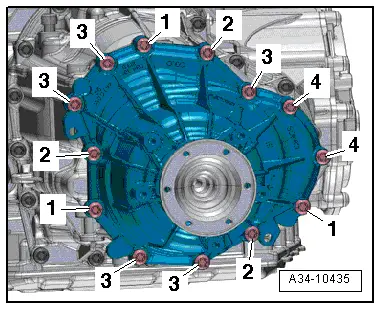

Note | Renew the bolts for the centre differential housing. |

| –

| Thoroughly clean both housing joint surfaces; they must be free from oil and grease. |

|

|

|

Note

Note

Note

Note

Caution

Caution WARNING

WARNING