A5

| Removing gearbox - vehicles with 4-cyl. petrol engine |

| Special tools and workshop equipment required |

| t | Removal lever -80 - 200- |

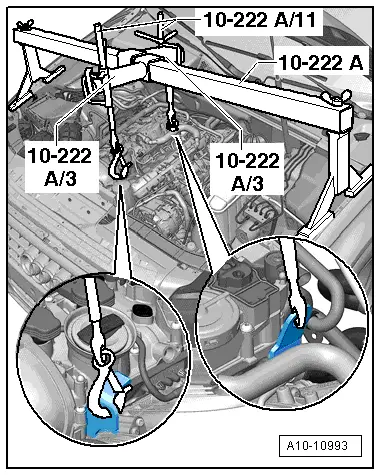

| t | Support bracket -10 - 222 A- |

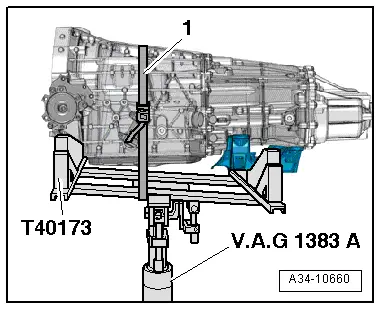

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Used oil collection and extraction unit -V.A.G 1782- |

| t | Engine bung set -VAS 6122- |

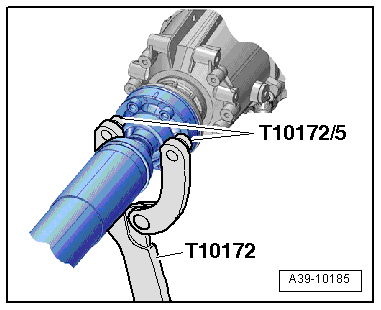

| t | Counterhold tool -T10172- with -T10172/5- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note |

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Caution

Caution