| Exploded view - propshaft with splines on gearbox end |

Note | t

| Refer to general repair instructions → Chapter. |

| t

| The propshaft of the type with splines on the gearbox end can only be separated from the gearbox by removing it completely. |

| t

| No repair work can be carried out on the propshaft with the exception of removing, installing and adjusting. |

| t

| The propshaft should normally be kept straight when it is stored or transported. |

| t

| The propshaft can be bent as far as the stop at the centre joint, but must not be subjected to any kind of force. The centre joint or the protective boot can be damaged if the joint is forced against its stop. |

| t

| The propshaft must be tied up or supported at one end if it is detached only at the rear final drive. If necessary, the propshaft can be bent as far as the stop at the centre joint, but it must not be subjected to force. |

| t

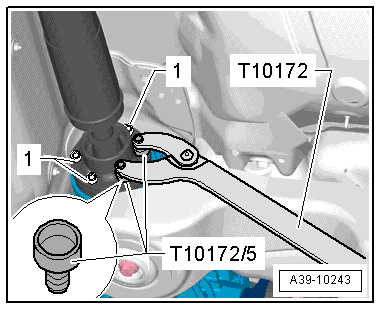

| Use counterhold tool -T10172- with adapters -T10172/5- to slacken and tighten the propshaft bolts. |

| t

| Always keep the propshaft horizontal while pulling it off or fitting it on the rear splined shaft of the gearbox. |

| t

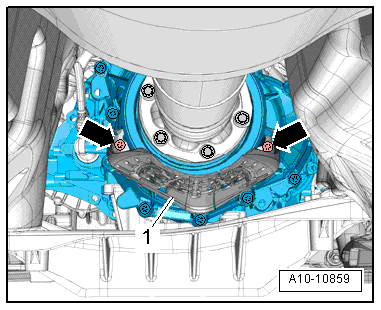

| Observe correct tightening sequence for bolts securing propshaft to rear final drive → Fig.. |

| Note the following before renewing the propshaft due to complaints concerning noise and/or vibrations. |

| t

| Check that centre bearing is free of stress or tension. |

| t

| Remove bolts securing propshaft to rear final drive. Re-tighten propshaft bolts in specified sequence → Fig.. |

|

|

|

Note

Note