A5

|

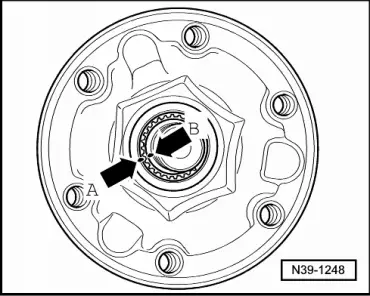

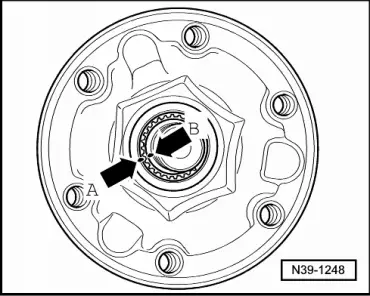

| Special tools and workshop equipment required |

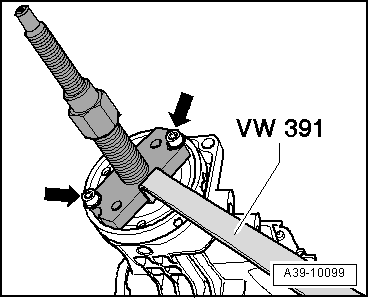

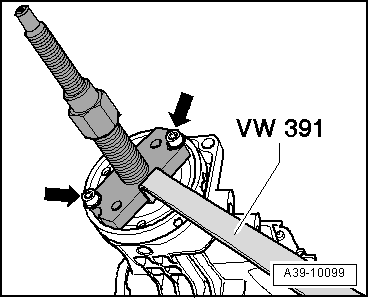

| t | Drive flange installing tool -VW 391- |

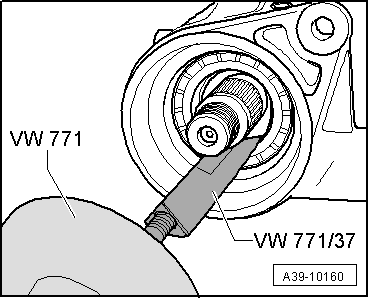

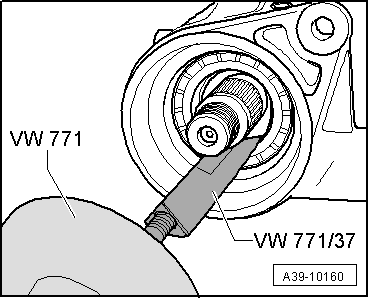

| t | Multi-purpose tool -VW 771- |

| t | Puller hook -VW 771/37- |

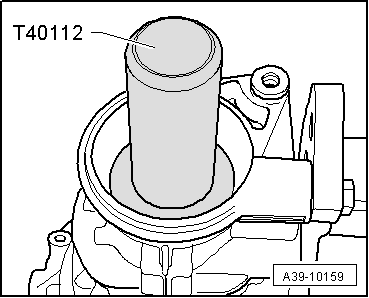

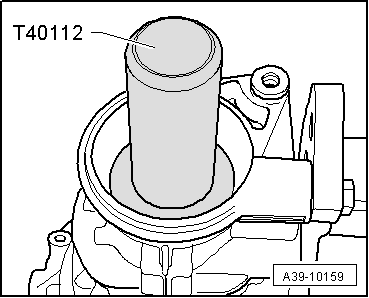

| t | Thrust piece -T40112- |

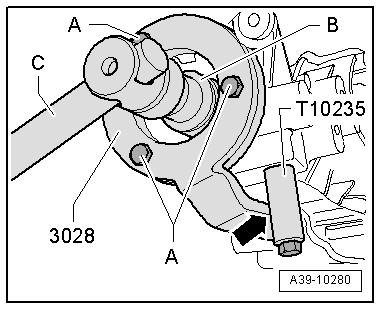

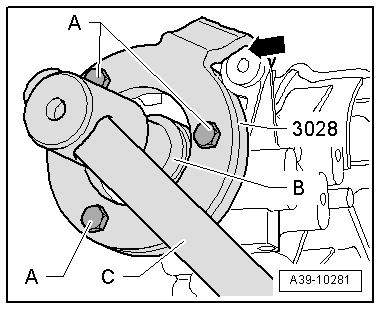

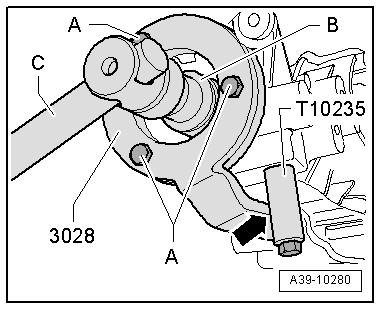

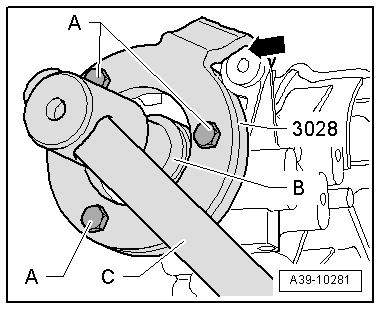

| t | Counterhold tool -3028- |

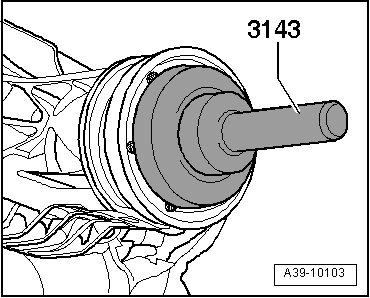

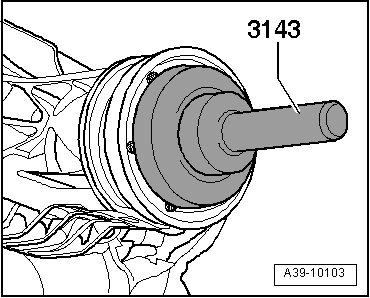

| t | Drift sleeve -3143- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Special tools and workshop equipment required |

| t | Drive flange installing tool -VW 391- |

| t | Multi-purpose tool -VW 771- |

| t | Puller hook -VW 771/37- |

| t | Thrust piece -T40112- |

| t | Counterhold tool -3028- |

| t | Drift sleeve -3143- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|