A5

| Removing and installing pressure plate and clutch plate („LuK“ version) |

| Special tools and workshop equipment required |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 412- |

| t | Thrust pad -VW 510- |

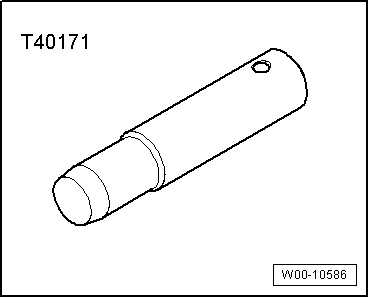

| t | Assembly tool -T10254- |

| t | Thrust piece -T40089- |

|

|

|

|

| Removing |

| – | Remove clutch module → Chapter. |

| 1 - | Clutch pressure plate |

Caution

Caution

|

| – | Position the clutch module so that the thrust pad -VW 510- makes contact with the bearing washer -arrow A- in the dual-mass flywheel. |

| – | Place the assembly tool -T10254/3- on the spring tongues in the diaphragm of the pressure plate -1- and apply the press. |

| l | Distance of travel: dimension -x- = 8 to 9 mm |

Note

Note| A second mechanic is required for the next step. |

| – | Remove all 6 bolts -2- and release press. |

| – | Remove pressure plate -1- and clutch plate. |

Note

Note

|

|

| – | Position the clutch module so that the thrust pad -VW 510- makes contact with the bearing washer -arrow A- in the dual-mass flywheel. |

| 1 - | Clutch pressure plate |

Caution

Caution

|

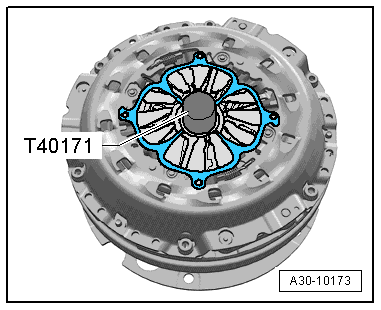

| – | Place assembly tool -T10254/3- over centring mandrel -T40171-. |

| – | Apply press until pressure plate -1- just makes contact with dual-mass flywheel -3--arrows C-. |

Note

Note| A second mechanic is required for the next step. |

| – | Screw in each of the 6 bolts -2- in succession and tighten to final torque. |

| – | Release press. |

| – | Install clutch module → Chapter. |