| l

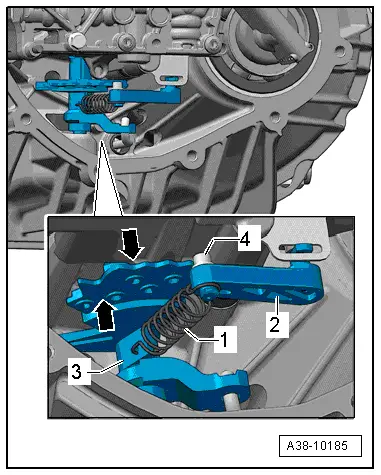

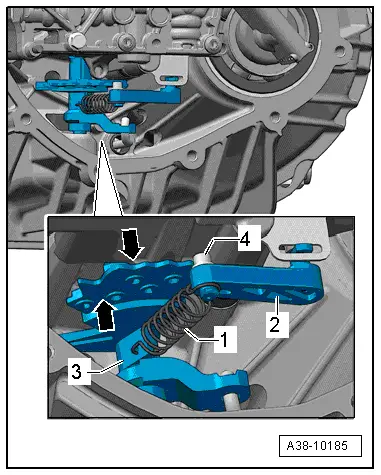

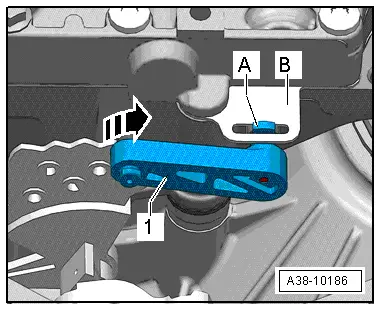

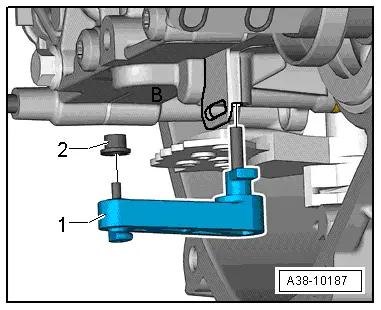

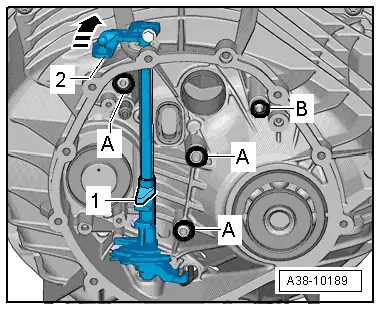

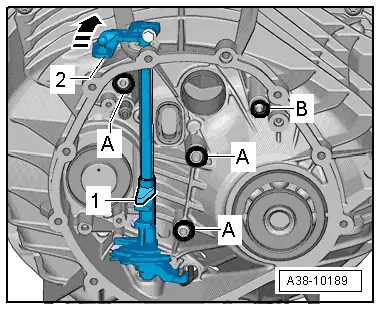

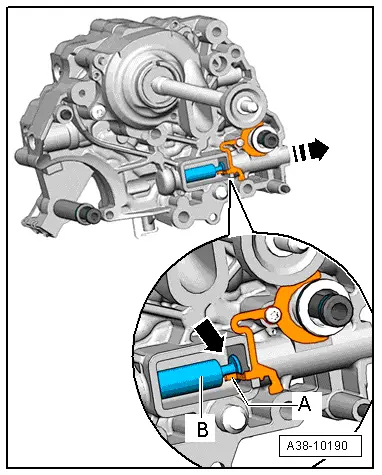

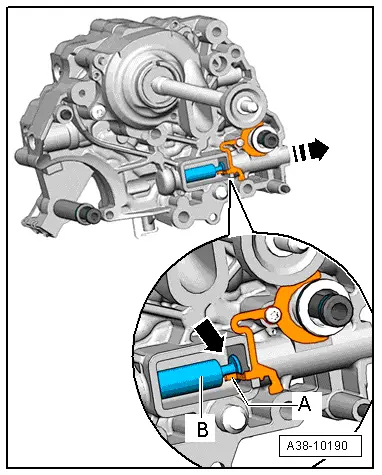

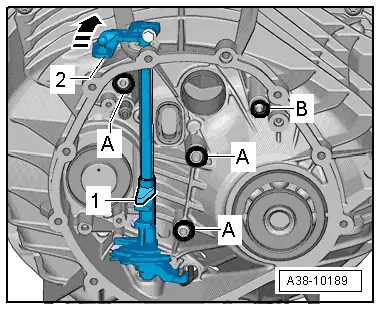

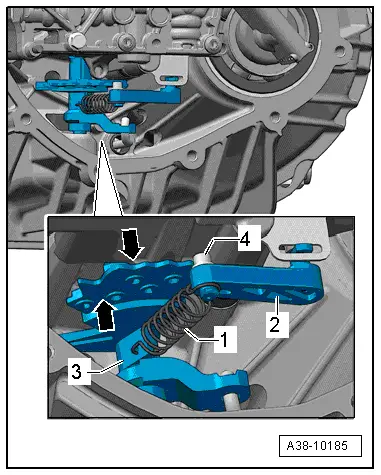

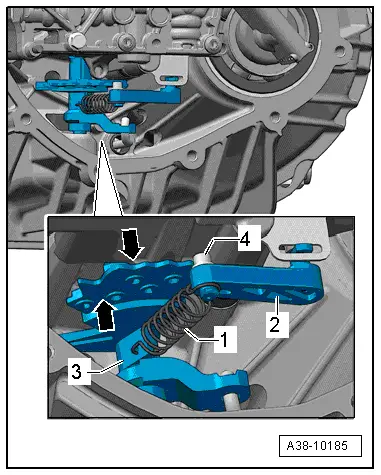

| The detent plate -top arrow- moves to the left and right. |

| l

| As it moves, the roller -4- should be able to engage in the individual notches one-by-one. |

| l

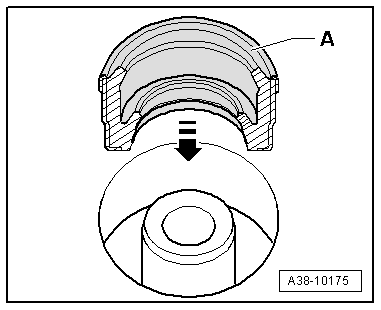

| Roller must be installed with the collar pointing downward, so that it cannot be pulled off upwards. |

| –

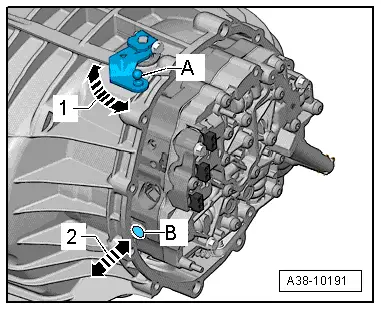

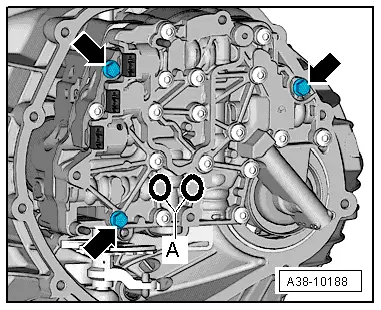

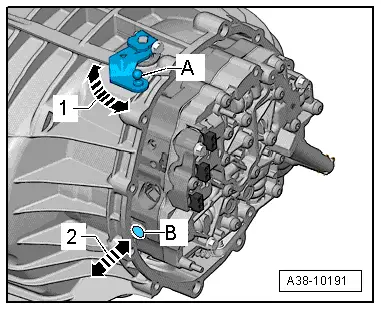

| Install automatic gearbox control unit -J217- → Chapter. |

Caution | If the hydraulic control unit has been renewed, carry out the following steps using a vehicle diagnostic tester: |

|

| –

| Using the diagnostic tester in Guided Fault Finding mode, go to Function/Component Selection and select the following menu items: |

| t

| 01 - Self-diagnosis-compatible systems |

| t

| 02 - Gearbox electronics |

| t

| 02 - Gearbox electronics, Functions |

| t

| 02 - Replace hydraulic control unit |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution