A5

| Poly V-belt drive - exploded view |

| 1 - | Poly V-belt |

| q | Check for wear |

| q | Before removing, mark direction of rotation with chalk or felt-tip pen. If the belt runs in the opposite direction when it is refitted, this can cause breakage. |

| q | Removing and installing → Chapter |

| q | When installing, make sure it is properly seated on pulleys. |

| 2 - | Vibration damper |

| q | Can only be installed in one position |

| q | Removing and installing → Chapter |

| 3 - | Cap |

| q | For vibration damper |

| 4 - | Bolt |

| q | Renew |

| q | 10 Nm + turn 90° further |

| 5 - | Bolt |

| q | Tightening torque → Rep. gr.48 |

| 6 - | Poly V-belt pulley |

| q | For power steering pump |

| 7 - | Tensioner |

| q | For poly V-belt |

| q | Use locking tool -T40098- to lock tensioner. |

| q | Removing and installing → Chapter |

| 8 - | Bracket |

| q | For ancillaries |

| q | Removing and installing → Chapter |

| 9 - | Bolt |

| q | Tightening torque → Electrical system; Rep. gr.27 |

| 10 - | Alternator |

| q | Removing and installing → Electrical system; Rep. gr.27 |

| 11 - | Bolt |

| q | 20 Nm + turn 180° further |

| 12 - | Power steering pump |

| q | Removing and installing → Rep. gr.48 |

| 13 - | Bolt |

| q | Renew |

| q | Tightening torque and sequence → Fig. |

| 14 - | Dowel sleeve |

| q | Ensure correct seating in bracket |

| 15 - | Air conditioner compressor |

| q | Do not unscrew or disconnect refrigerant hoses or pipes. |

| q | Removing and installing → Rep. gr.87 |

| q | Pay attention to dowel sleeves → Item when installing |

| 16 - | Bolt |

| q | Tightening torque → Rep. gr.87 |

| 17 - | Bolt |

| q | Tightening torque → Rep. gr.48 |

| 18 - | Idler roller |

| q | For poly V-belt |

| q | With cover cap |

| q | Note installation position |

| 19 - | Bolt |

| q | Renew |

| q | 20 Nm + turn 90° further |

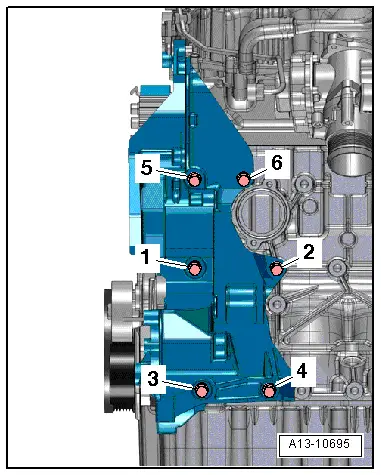

| Stage | Bolts | Tightening torque/angle specification |

| 1. | -1 … 6- | Screw in bolts by hand until they make contact |

| 2. | -1 … 6- | 40 Nm |

| 3. | -1- and -2- | turn 60° further |

| 4. | -3- and -4- | turn 180° further |

| 5. | -5- and -6- | turn 60° further |

Note

Note