A5

| Pistons and conrods - exploded view |

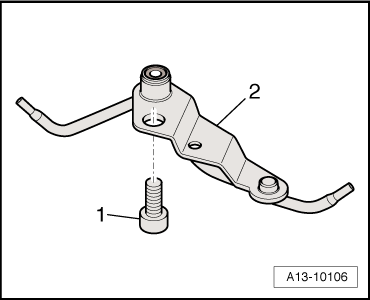

| 1 - | Bolts |

| q | Renew |

| q | Lubricate threads and contact surface |

| q | 50 Nm + turn 90° further |

| 2 - | Conrod bearing cap |

| q | Mark installation position for re-installation |

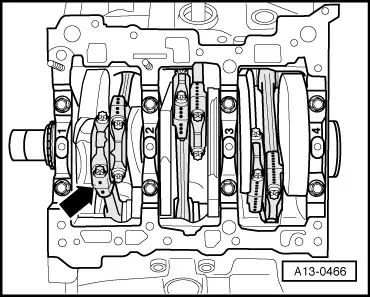

| q | Mark cylinder and conrod allocation in colour → Fig. |

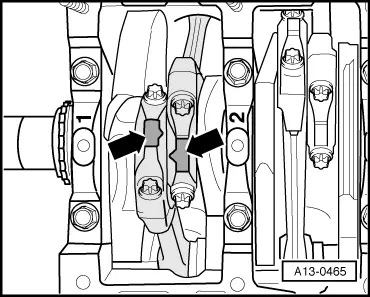

| q | Installation position of conrod pairs → Fig. |

| 3 - | Bearing shells |

| q | Ensure that retaining lugs are securely seated. |

| q | Renew used bearing shells |

| q | There are oversized bearings available for machined crankshaft conrod journals → Electronic parts catalogue |

| q | Lugs on conrod bearings must be on the same side |

| 4 - | Conrod |

| q | Only renew as a complete set |

| q | Mark cylinder and conrod bearing cap allocation in colour → Fig. |

| q | Installation position of conrod pairs → Fig. |

| q | Axial clearance for each conrod pair (when new): 0.20 … 0.45 mm |

| q | Measuring radial clearance → Chapter |

| 5 - | Circlip |

| q | Renew |

| 6 - | Piston pin |

| q | Removing and installing → Chapter „Removing and installing pistons“ |

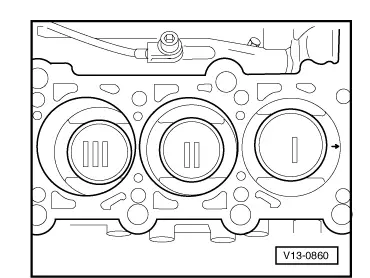

| 7 - | Piston |

| q | Mark installation position and cylinder number → Fig. |

| q | Removing and installing → Chapter |

| q | Renew piston if cracking is visible on piston crown or piston skirt |

| q | Checking pistons and cylinder bores → Chapter |

| 8 - | Piston rings |

| q | Measuring ring gap → Fig. |

| q | Measuring ring-to-groove clearance → Fig. |

| q | Use piston ring pliers (commercially available) to remove and install |

| q | Installation position: marking „TOP“ or side with lettering faces towards piston crown |

| q | Offset gaps by 120° |

Note

Note

|

|

|

|

|

|

Caution

Caution