A5

| Poly V-belt drive - exploded view |

| 1 - | Bolt |

| q | 22 Nm |

| 2 - | Bolt |

| q | 55 Nm |

| 3 - | Tensioner for poly V-belt |

| q | Removing and installing → Chapter |

| 4 - | Poly V-belt |

| q | Check for wear |

| q | Before removing, mark direction of rotation with chalk or felt-tip pen |

| q | Removing and installing → Chapter |

| q | Do not kink |

| q | When installing, make sure it is properly seated on pulleys |

| 5 - | Bolt |

| q | 22 Nm |

| 6 - | Alternator |

| q | Removing and installing → Electrical system; Rep. gr.27 |

| 7 - | Bolt |

| q | Tightening torque → Electrical system; Rep. gr.27 |

| 8 - | Bolt |

| q | 46 Nm |

| 9 - | Bracket for alternator |

| 10 - | Dowel sleeve |

| q | For bracket for alternator |

| q | 2x |

| 11 - | Cover for idler roller |

| 12 - | Bolt |

| q | 9 Nm |

| 13 - | Bearing bracket |

| q | For idler roller |

| 14 - | Idler roller for poly V-belt |

| 15 - | Bolt |

| q | 22 Nm |

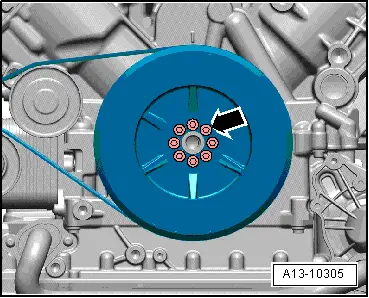

| 16 - | Vibration damper |

| q | With poly V-belt pulley |

| q | Removing and installing → Chapter |

| 17 - | Bolt |

| q | Renew |

| q | Threaded holes for bolts must be cleaned using a thread tap or similar |

| q | Apply locking fluid when installing; refer to → Electronic parts catalogue |

| q | Tightening torque and sequence → Fig. |

| 18 - | Thrust washer |

Note

Note

|

|

| Stage | Bolts | Tightening torque/angle specification |

| 1. | -arrow- | 15 Nm in diagonal sequence |

| 2. | -arrow- | 22 Nm in diagonal sequence |

| 3. | -arrow- | Turn 90° further in diagonal sequence |