A5

|

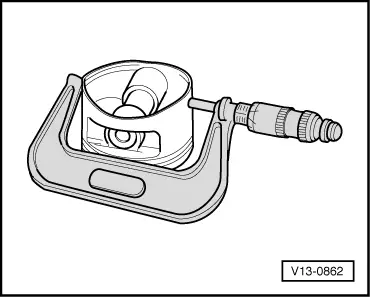

| Piston Ø mm | |||

| For nominal bore dimension I | 84.490 1) | ||

| For nominal bore dimension II | 84.590 1) | ||

| |||

|

|

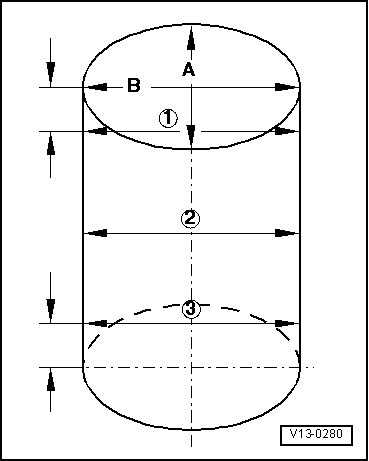

| Cylinder bore Ø mm | |

| Nominal bore dimension I | 84.510 ± 0.005 |

| Nominal bore dimension II | 84.610 ± 0.005 |

|

|

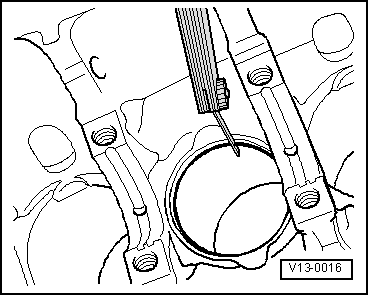

| Piston ring | new mm | Wear limit mm |

| 1st compression ring | 0.20 … 0.35 | 0.80 |

| 2nd compression ring | 0.20 … 0.40 | 0.80 |

| Oil scraper ring | 0.20 … 0.40 | 0.80 |

|

|

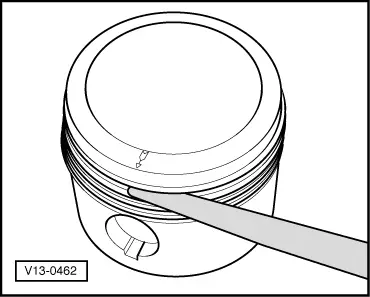

| Piston ring | new mm | Wear limit mm |

| 1st compression ring | 0.035 … 0.085 | 0.200 |

| 2nd compression ring | 0.005 … 0.045 | 0.150 |

| Oil scraper ring | 0.010 … 0.050 | 0.200 |