DeVille V8-273 4.5L (1989)

Hose/Line HVAC: All Technical Service Bulletins

A/C - Insufficient Cooling/Poor Performance

Bulletin No.

T-91-48A

File in Group

1

Number

72

Corp. Ref. No.

911205R

Date

March, 1991

SUBJECT:

A/C SYSTEM HIGH PRESSURE RELIEF VALVE "BLOW-OFF"

MODELS AFFECTED:

1989-1991 DE VILLES AND FLEETWOODS

This bulletin supersedes Service Bulletin T-91-48 which should be discarded. This bulletin is being revised to correct the Group number and the

Corporate reference number.

This bulletin supersedes Service Bulletin T-90-23 which should be discarded. This bulletin is being revised to incluae 1991 model year, include 1991

part number, change operation number, and revise the oil distribution.

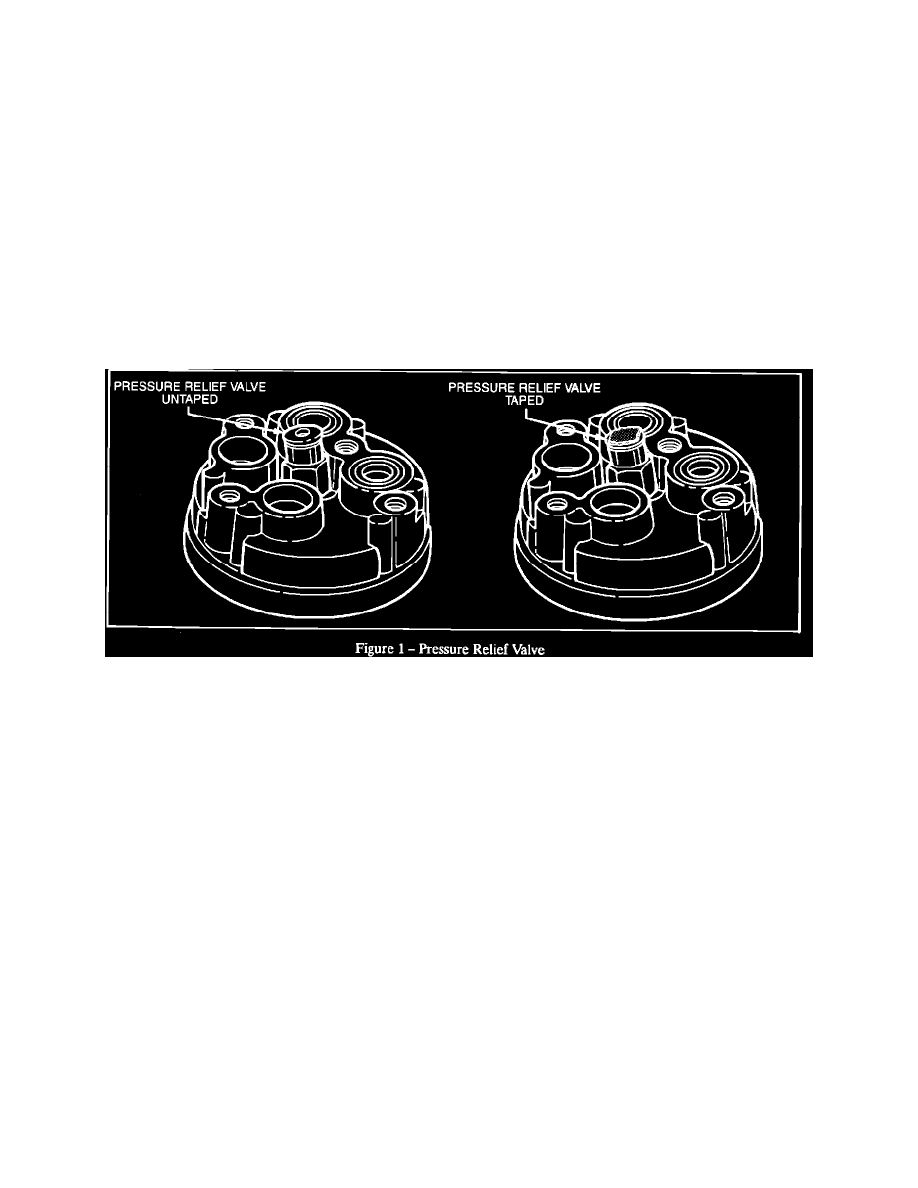

Some 1989-1991 DeVille and Fleetwood A/C systems may experience an insufficient cooling or system condition due to refrigerant "blow-off " at the

pressure relief valve found on the rear head of the compressor. Refer to Figure 1. This may be caused by a knock-out slug (from the muffler) becoming

caught in the discharge hose assembly.

In the case of an inoperative system, always check for a refrigerant discharge through the pressure relief valve. As seen in the illustrations below, if the

relief valve has not been released the piece of tape will be intact across the valve. Refer to Figure 1. Upon discharge from this valve the tape will be torn

free and evidence of refrigerant oil will appear about the valve and surrounding area.

If the pressure relief valve has opened and released refrigerant, use the following procedure:

CAUTION: Before any service is attempted which requires opening of the refrigerant system, the technician should be thoroughly familiar with the

important information contained under the heading "On-Car Service" in Section 1C of the Service Information Manual.

1.

Check the following:

a.

Outer surfaces of radiator and condenser cores for blockage. Check between the condenser and radiator. Clean as needed.

b.

Restrictions or kinks in evaporator and condenser cores, hoses, tubes, etc. Replace as needed.

c.

Cooling fan operation. Repair as needed.

d.

Air ducts for leaks and restrictions. Low air flow may mean a restricted or frozen evaporator core. Repair as needed.

e.

Compressor clutch for slippage. Check compressor clutch coil current (3-6 amps) and compressor clutch. Refer to Section 8A for

electrical schematics. Repair/replace as needed.

f

Drive belt for improper tension or excessive wear. Replace as needed.

g.

Orifice tube for plugged condition. Clean or replace as needed.