Econoline E350 1 Ton V8-5.4L Prop SOHC VIN Z (1998)

Differential Case: Service and Repair

Disassembly and Assembly

Dana

Special Tools

DISASSEMBLY

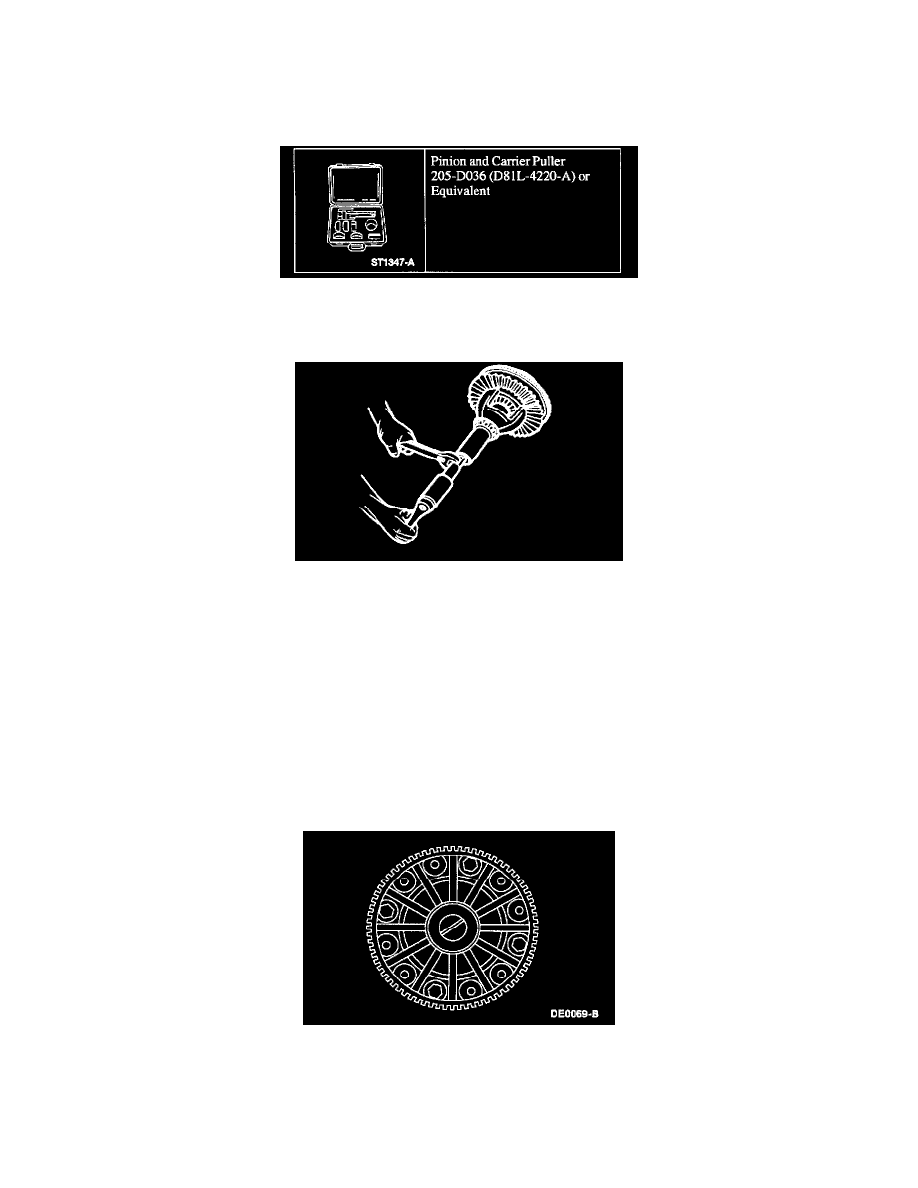

1. Remove the differential bearings with the Pinion and Carrier Bearing Puller.

-

Wire the differential bearing shims, differential bearing cup, differential bearing and outboard selective spacer together. Note from which side

they were removed (ring gear side or opposite side).

NOTE: Differential bearing shims are available in thicknesses of 0.762, 0.787, 0.813, 0.838, 0.864, 0.889 and 0.914 mm (0.030, 0.031,

0.032, 0.033, 0.034, 0.035 and 0.036 inch).

NOTE: If differential bearing shims are damaged, replace with new ones.

NOTE: Replace the differential bearings whenever they are removed from the rear axle differential carrier.

2. Place the differential case in a vise.

NOTE: Place a few shop towels over the vise to prevent the teeth of the ring gear from being nicked.

3. Remove the bolts on the ring gear. Leave four bolts loosely assembled, 90 degrees apart.

CAUTION: Use care not to damage the anti-lock speed sensor ring when removing the ring gear. If the anti-lock speed sensor ring is removed, it

must be replaced with a new one.

NOTE: Whenever removing the ring gear bolts, always replace them with new bolts upon assembly. Use Grade 9 bolts for service replacement