Inspection of Crankshaft for 300Tdi Engine Overhaul

ENGINE

58

OVERHAUL

Crankshaft - inspection

NOTE: Crankshafts may be reground 0.25

mm undersize on both main and big-end

journals.

See Crankshaft - regrinding.

1. Clean crankshaft and main bearing caps,

ensure oilways are clear.

2. Check main and big-end journals for signs of

scoring, excessive wear and overheating.

3. Check main and big-end bearing journals for

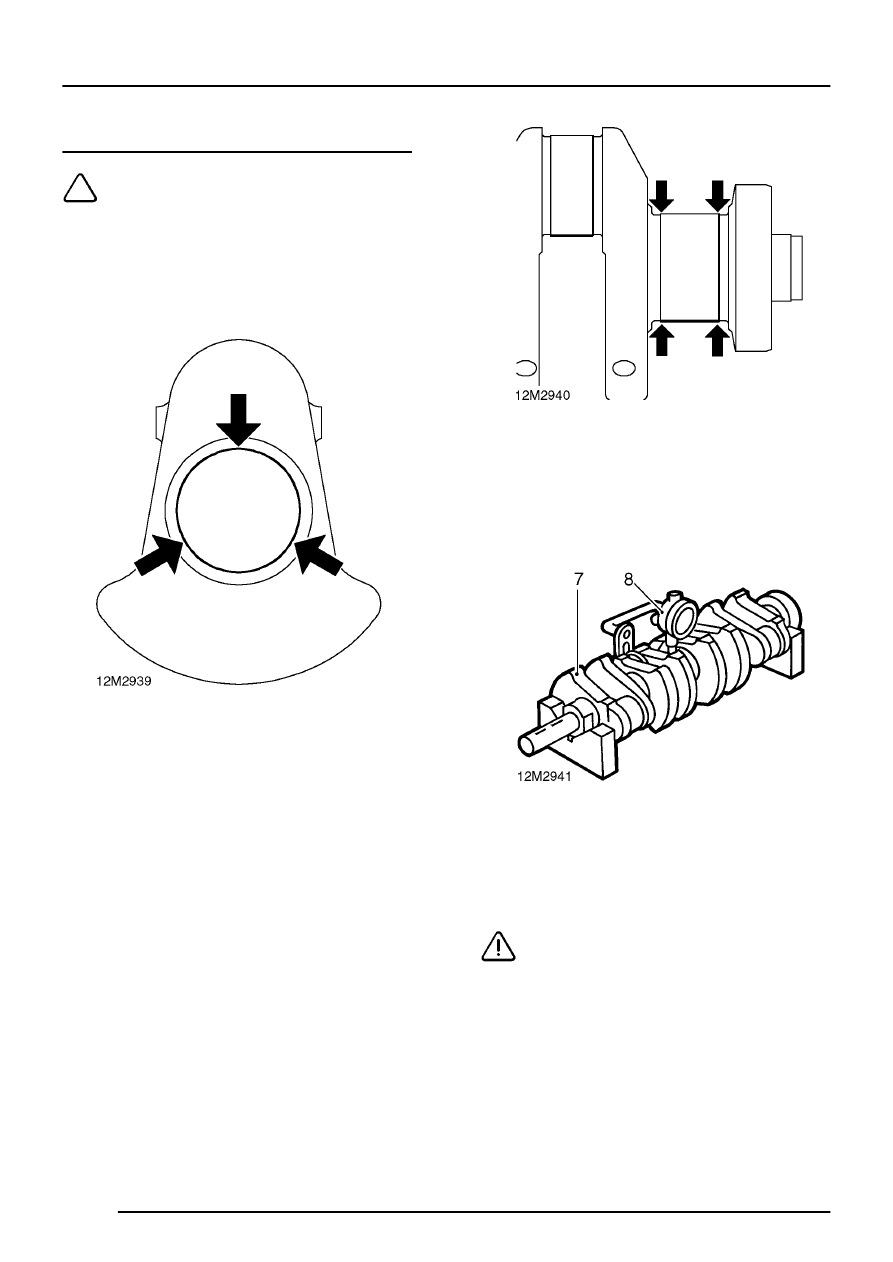

wear and ovality, make 3 checks at 120

°

intervals in centre of journals.

Maximum ovality = 0.040 mm

Main bearing journal diameter = 63.475 to

63.487 mm

Service limit = 63.36 mm

Regrind diameter = 63.225 to 63.237 mm

Big-end bearing journal diameter = 58.725 to

58.744 mm

Service limit = 58.637 mm

Regrind diameter = 58.475 to 58.494 mm

4. If bearing journal diameters are less than

service limit, crankshaft may be reground to

specified regrind diameter and 0.25 mm

oversize bearing shells fitted.

5. Using a micrometer, measure diameter at each

end of main and big-end bearing journals.

6. From measurements obtained, calculate taper

of each journal.

Maximum journal taper - end to end = 0.025

mm

7. Support each end of crankshaft in Vee blocks.

8. Position a DTI with stylus contacting centre

main bearing journal.

9. Rotate crankshaft and check run-out does not

exceed 0.076 mm.

CAUTION: If run-out exceeds above figure,

renew crankshaft.