Cylinder block inspection for 300Tdi engine overhaul

ENGINE

76

OVERHAUL

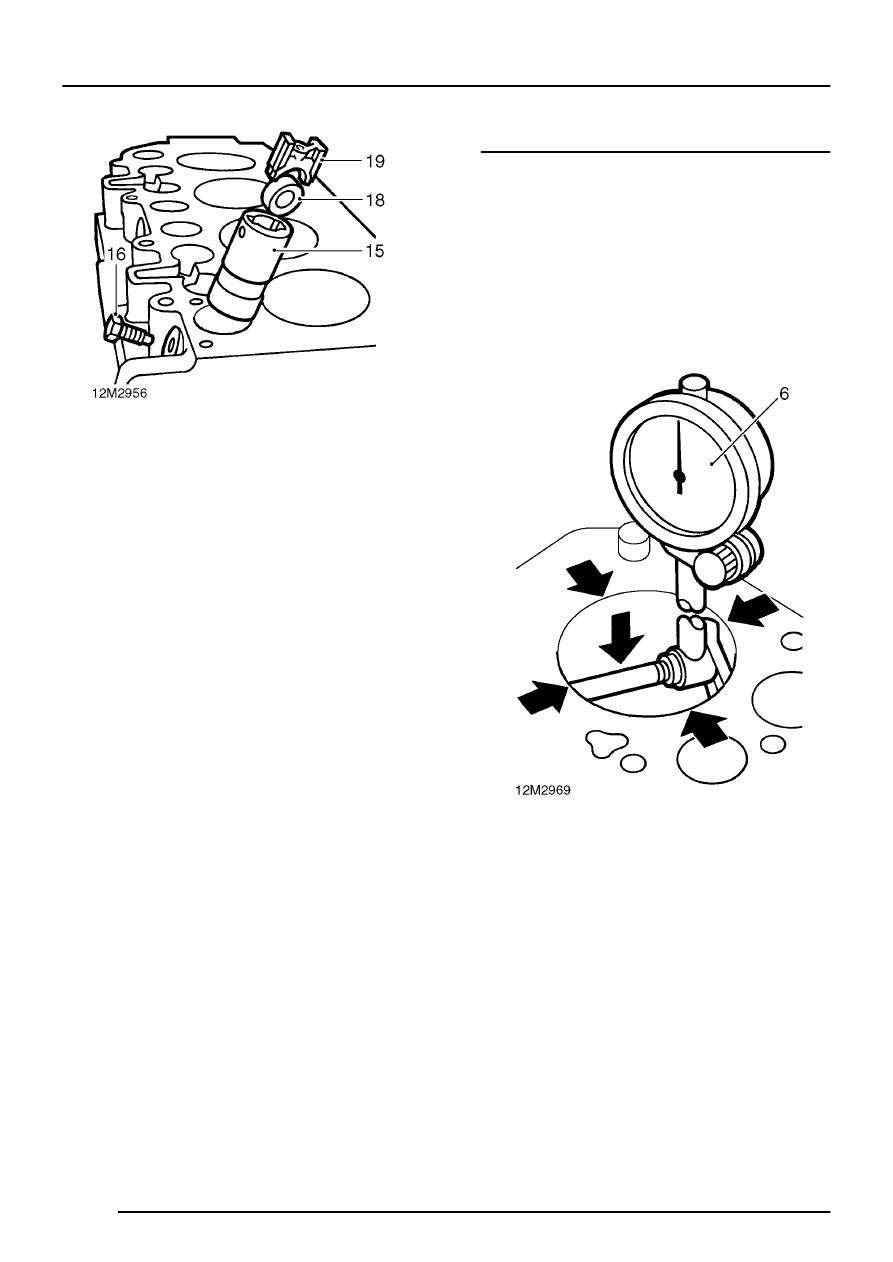

15. Insert each cam follower guide into its original

location in the cylinder block.

16. Fit new retaining bolt, locate end of bolt in cam

follower guide.

17. Tighten bolt to 14 Nm.

18. Fit roller ensuring that reference mark made

during removal is towards front of cylinder

block.

19. Fit cam follower slide ensuring that word

’FRONT’ or mark ’F’ is towards front of cylinder

block.

20. Repeat above procedures for remaining cam

follower assemblies.

21. Fit a dry, new gasket to baffle plate.

22. Fit baffle plate, fit 3 bolts and finger tighten in

their original locations.

23. Bolts are tightened when fuel injection pump is

fitted.

Cylinder block - inspection

1. Thoroughly clean cylinder block, ensure all bolt

holes are clean and dry.

2. Remove all traces of carbon from cylinder head

gasket face.

3. Remove all traces of gaskets using suitable

gasket removal spray and a plastic scraper.

4. Check all studs for damage, replace as

necessary.

5. Check core plugs for corrosion and signs of

leakage, replace as necessary.

6. Using an internal micrometer, take 2

measurements at 90

°

to each other at top of

bore. The difference between the 2

measurements is the ovality of the bore.

Maximum ovality = 0.127 mm

7. Repeat measurements 50 mm from bottom of

each cylinder bore.

8. Measure from side to side from below wear

ridge at top of bore and above wear ridge at

bottom of bore. The difference between the 2

measurements is the taper.

Maximum taper = 0.254 mm