Cylinder Head Gasket Selection Guide for 300Tdi Engine

ENGINE

OVERHAUL

27

Valves and springs - refit

1. Lubricate valve stems, guides, spring seats,

valve springs, spring cups and collets with

engine oil.

2. Lubricate new valve stem oil seals with engine

oil and fit to valve guides.

3. Fit spring seat, insert valve into its respective

guide, fit valve spring and spring cup.

4. Compress valve spring using tool LRT-12-034

and fit collets.

5. Remove tool LRT-12-034.

6. Tap spring cup with a soft mallet to ensure that

collets are correctly seated.

7. Repeat above procedures for remaining

valves.

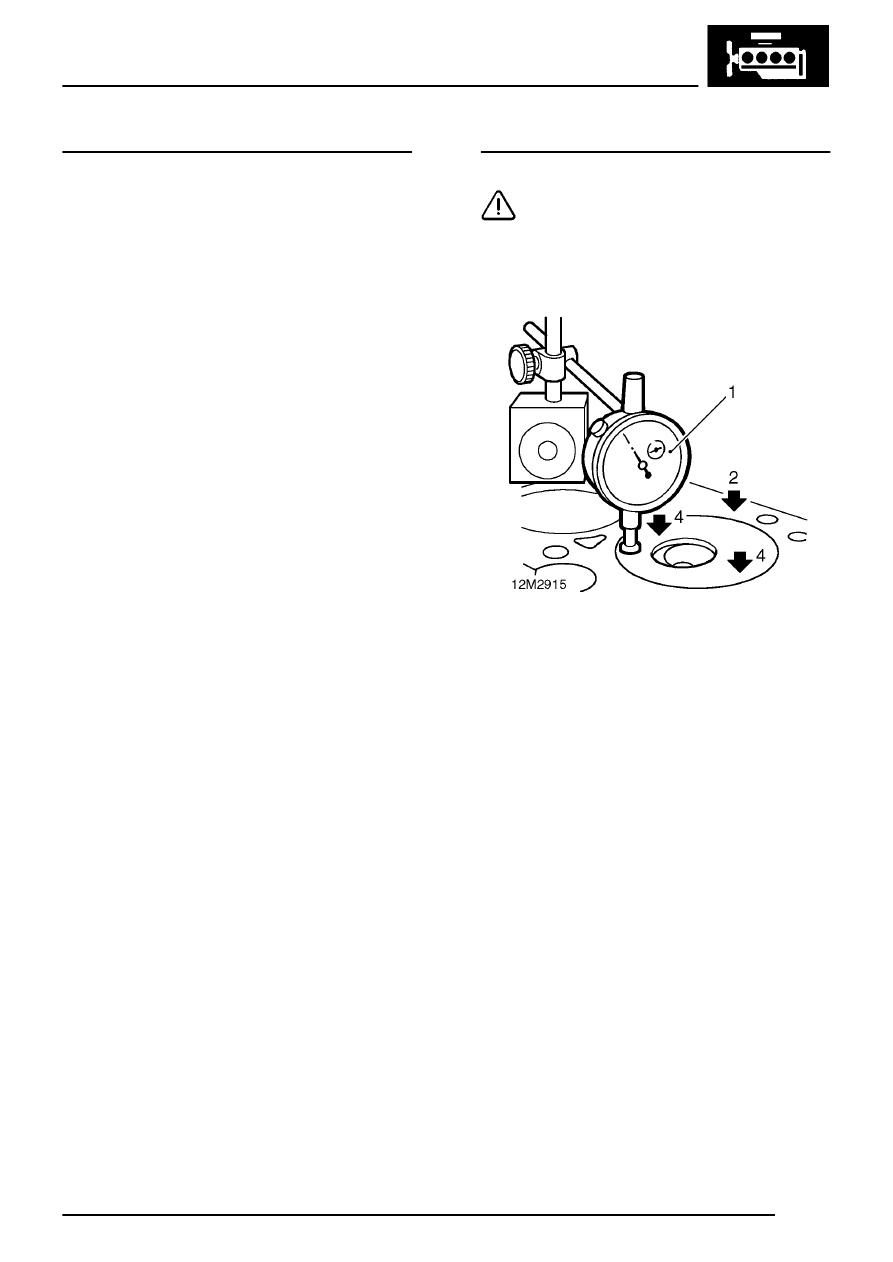

Cylinder head gasket selection

CAUTION: New cylinder head gasket

should be same thickness as the original.

If, however, cylinder head, pistons or

crankshaft have been replaced, it will be

necessary to check piston stand proud in order

to determine the correct thickness of gasket.

1. Position a magnetic base DTI to cylinder block

top face adjacent to number 1 cylinder bore.

2. Position stylus of gauge to cylinder block top

face on edge of number 1 cylinder bore; zero

gauge.

3. Rotate crankshaft in a clockwise direction until

numbers 1 and 4 pistons are at TDC.

4. Position stylus of DTI gauge near edge of

piston crown, measure and record number 1

piston stand proud. Measurement must be

taken at front and rear of piston and highest

protrusion figure recorded.

5. Repeat above procedures for remaining

pistons.