300Tdi Defender

COOLING SYSTEM

3

DESCRIPTION AND OPERATION

COOLANT CIRCULATION

Operation

When the engine is started from cold the thermostat

(2) prevents coolant circulation through the radiator by

closing off the top hose (6). During the engine warm

up period the water pump (5) circulates coolant to the

cylinders in the crankcase and through separate ports

to the cylinder head. At the rear of the cylinder head a

proportion of the flow is diverted through a heater feed

pipe (16) to the matrix of the heater unit (15). The

coolant is then carried, via a heater return rail (14) and

hoses (7), back to the water pump. The remaining

coolant flows through a by-pass hose (9) at the

thermostat housing and back to the water pump to

complete the first cycle.

When the normal engine running temperature is

reached, the thermostat opens, closing off the by-pass

hose (9). Coolant is then circulated via the top hose

(6) and through the radiator, where it is cooled and

drawn from the radiator bottom hose (3) by the water

pump (5). The coolant circulation through the

crankcase and cylinder head remains the same.

Two bleed pipes (10) and (11) help control the system

pressure by purging excess air and coolant to the

expansion tank via the ’Y’piece ejector (12).

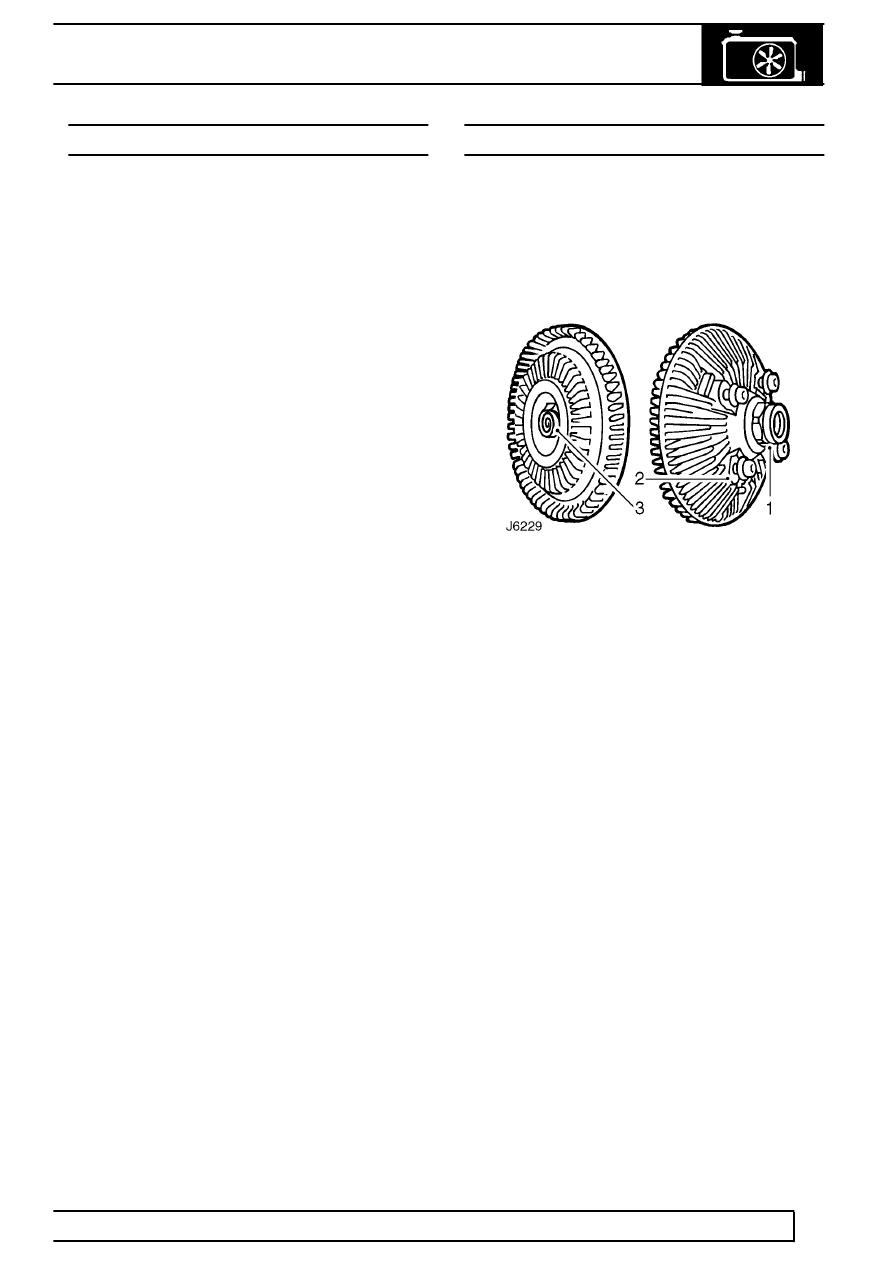

VISCOUS FAN

Description

The viscous drive unit for the engine cooling fan,

provides a means of controlling the speed of the fan

relative to the running temperature of the engine. The

viscous unit is a type of fluid coupling, which drives

the fan blades by means of ’silicone fluid’.

1. Input (drive) member

2. Output (driven) member

3. Sensing mechanism (bi-metal coil)

The fan drive has to be engaged only periodically,

between 5% and 10%, during normal operating

conditions, because the engine is cooled by ram air

for most of the time.