300Tdi Defender

26

COOLING SYSTEM

4

DESCRIPTION AND OPERATION

Operation

To engage and disengage the fan drive the bi-metal

coil senses air temperature behind the radiator. When

a pre-determined temperature is reached, the coil

opens a valve (5) which allows fluid to enter the drive

area and, due to centrifugal force, circulates to the

annular drive area.

There are two sets of annular grooves (3), one in the

drive clutch and the other in the drive body, a specific

clearance being provided between the two sets of

grooves.

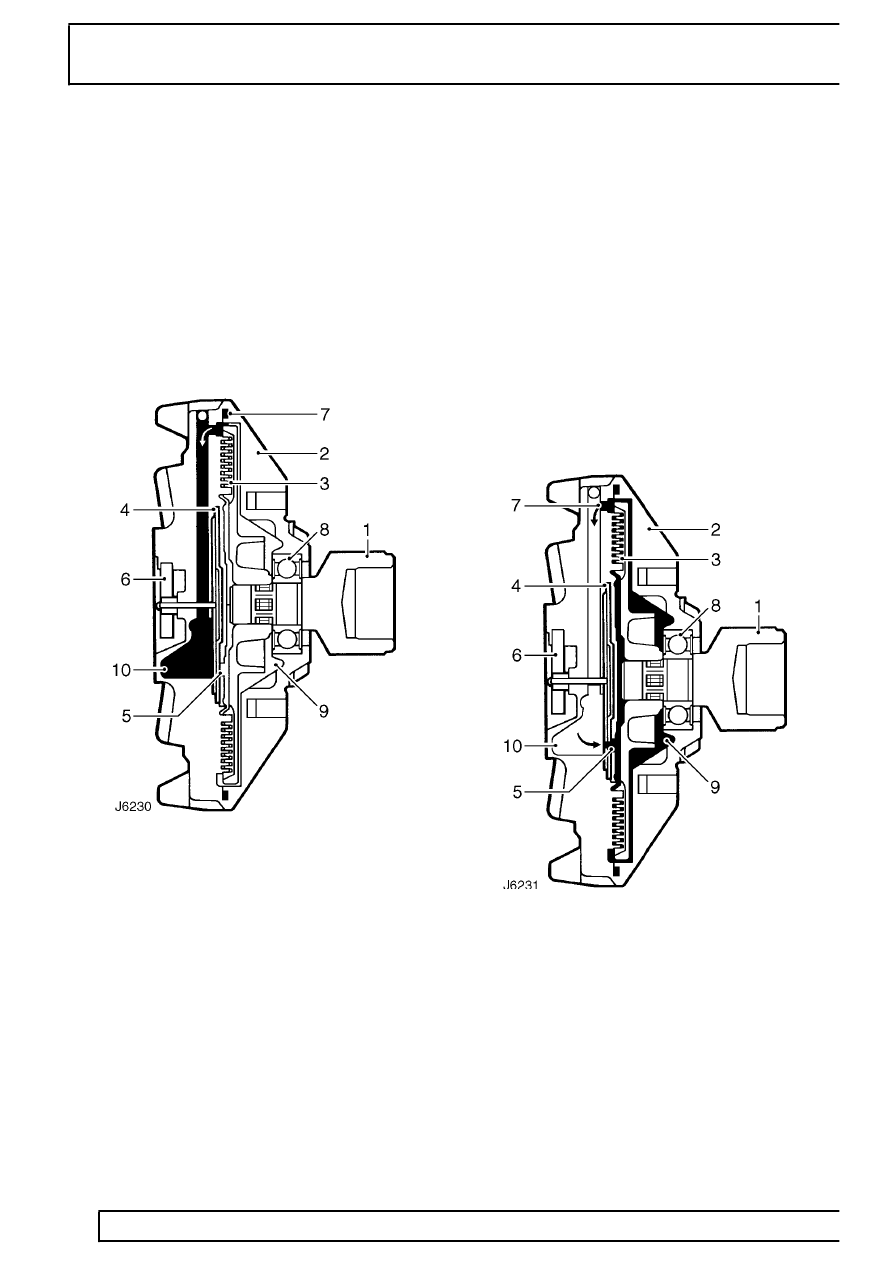

Viscous unit disengaged (engine at normal

running temperature)

1. Input (drive) member

2. Output (driven) member

3. Running clearance

4. Pump plate

5. Valve (closed)

6. Sensing mechanism (bi-metal coil)

7. Fluid seal

8. Bearing, input member

9. Fluid chamber

10. Fluid reservoir

When this clearance is filled with viscous fluid, a

shearing action, caused by the speed differential

between the two drive components, transmits torque

to the fan. The fluid is thrown to the outside of the unit

by centrifugal force from where it is recirculated to the

reservoir (10) via the pump plate (4) adjacent to the

drive member.

If the engine speed is increased the amount of slip will

also increase to limit the maximum fan speed.

When the air temperature from the radiator drops

sufficiently, the bi-metal coil closes the valve and

prevents fluid entering the drive area. The fluid that is

in the drive area will gradually pump out into the

reservoir (10) and the fan will return to an idle

condition.

Viscous unit engaged (hot running temperature)

Bi-metal coil (6) expanded, valve (5) open.