300Tdi Defender

ENGINE

1

REPAIR

CYLINDER COMPRESSION TEST

Service repair no - 12.25.01

1. Start and run engine to normal operating

temperature.

2. Switch off engine.

3. Disconnect spill return hose and fuel pipe from

No.1 injector.

4. Remove retaining nut, release clamp and

withdraw injector from cylinder head.

See FUEL

SYSTEM, Repair, injectors

5. Disconnect electrical lead from fuel cut-off

solenoid at injection pump to prevent delivery of

fuel to injectors. On vehicles fitted with a digital

diesel shut-off valve (DDS) immobilisation

system, disconnect DDS multi-plug.

6. Ensure injector port is clean, If necessary, crank

the engine a few revolutions to remove any

loose carbon.

7. Fit dummy injector, from diesel compression

tester kit LRT-19-007, into the cylinder head and

clamp securely in position.

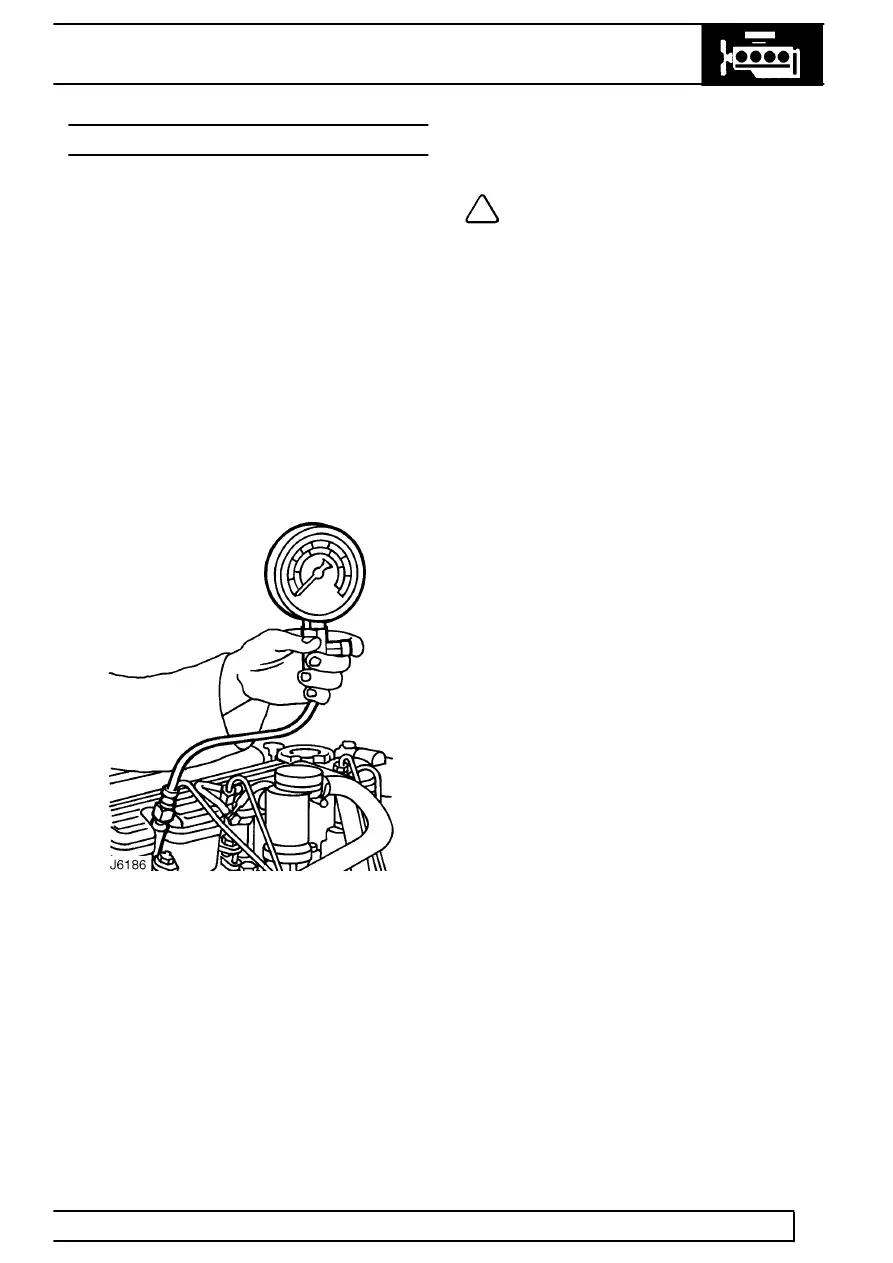

8. Connect flexible hose and gauge to dummy

injector as shown above.

9. Crank engine for 10-20 seconds and note

reading on gauge. The gauge will indicate the

compression of the cylinder and maintain the

reading until the pressure release valve on the

gauge is depressed.

Expected readings of a crank test, with vehicle

battery fully charged, compression ratio 19.5:1

should be 24 bar (348 lbf/in

2

).

10. Repeat test procedure for remaining clinders in

turn.

NOTE: A variation in compression

readings between cylinders is often a

better indication of an engine problem

than the absolute values of compression.

11. If compression is appreciably less than correct

reading, or varies by more than 10%, piston

rings or valves may be worn or damaged.

Low pressures in adjoining cylinders may

indicate a faulty cylinder head gasket.