300Tdi Defender Engine Valve Clearance Check and Adjustment for Improved Performance

ENGINE

1

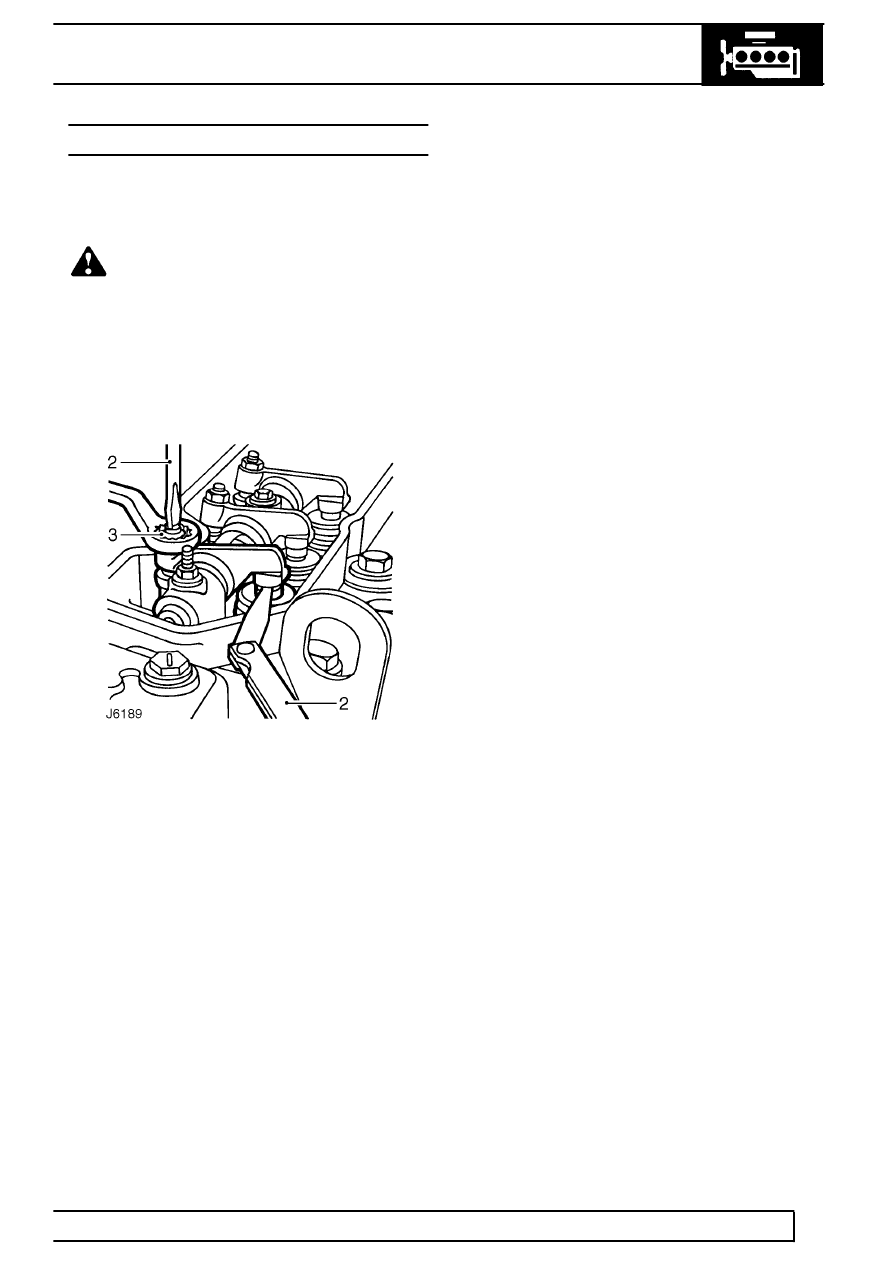

ADJUSTMENT

VALVE CLEARANCES - CHECK AND ADJUST

Service repair no - 12.29.48

Adjust

WARNING: If the crankshaft is rotated with

excessive valve clearace, it is possible

that the push rods could be dislodged

from the cam follower seating and fracture the

cam follower slide. To prevent damage, eliminate

all clearance from any loose rockers before

turning the crankshaft to adjust clearances.

1. Rotate crankshaft until No.8 valve (counting from

front of engine) is fully open.

2. Using a 0,20 mm (0.008 in) feeler gauge adjust

clearance of No.1 valve.

3. Slacken locknut and turn adjusting screw

clockwise to reduce clearance and

anti-clockwise to increase clearance. Tighten

locknut to

16 Nm (12 lbf/ft).

4. Repeat operation for remaining tappets in the

following sequence:

No.3 tappet with No.6 valve fully open.

No.5 tappet with No.4 valve fully open.

No.2 tappet with No.7 valve fully open.

No.8 tappet with No.1 valve fully open.

No.6 tappet with No.3 valve fully open.

No.4 tappet with No.5 valve fully open.

No.7 tappet with No.2 valve fully open.

5. On completion, recheck clearances and adjust

as necessary.