Assemble Rear Axle and Final Drive for 300Tdi Defender

51

REAR AXLE AND FINAL DRIVE

4

OVERHAUL

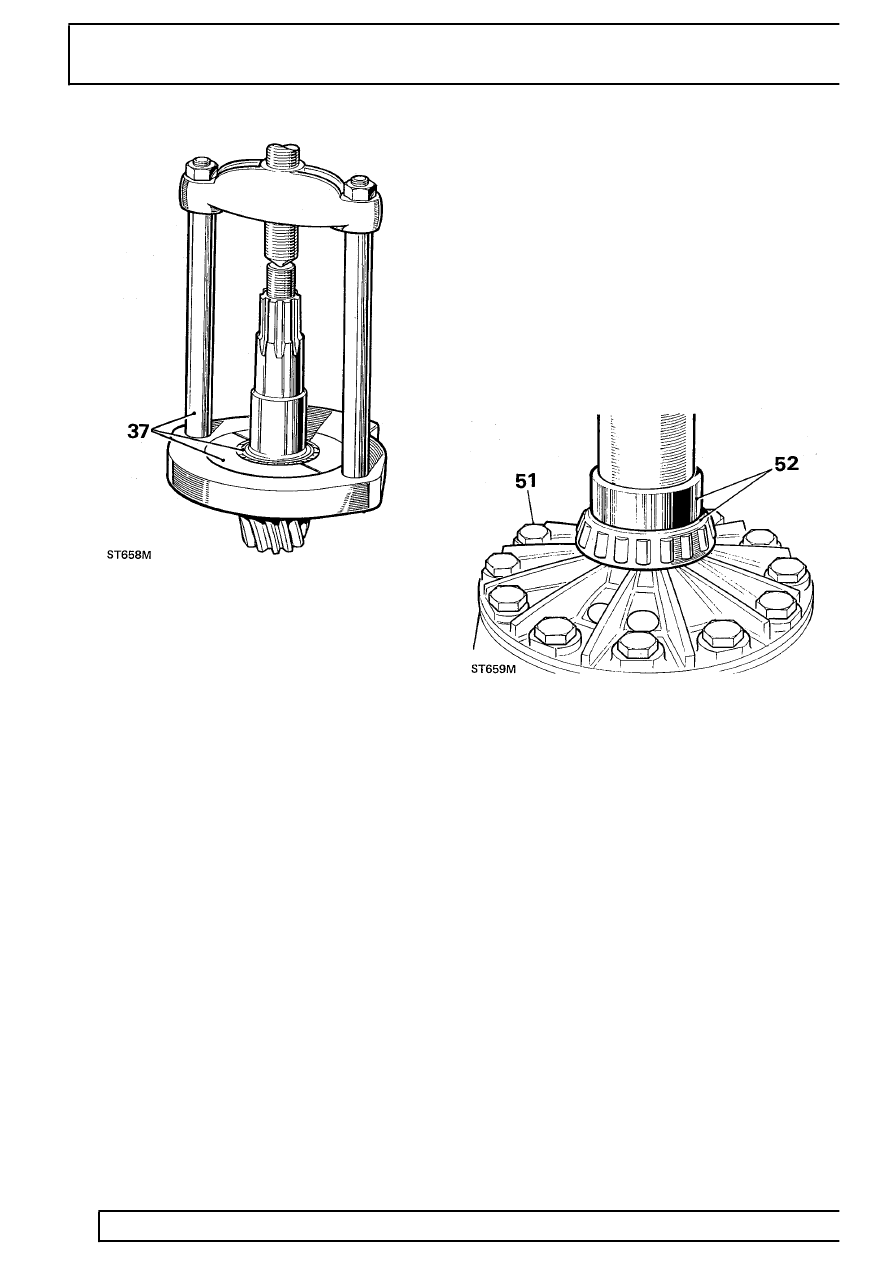

37. Using LRT-51-500 and press LRT-99-002,

remove inner bearing cone from pinion.

INSPECTION

38. Examine all components for obvious wear or

damage.

39. Bearing cones must be a press fit on their

locations, except drive pinion flange and bearing

which is a slide fit.

40. The crown wheel and pinion are supplied as a

matched pair and must not be interchanged

separately. A new crown wheel and pinion

matched pair may be fitted to an original gear

carrier casing if sound. original crown wheel and

pinion, if sound, may be fitted into a replacement

casing.

41. The two parts of differential unit casing are

matched and must not be replaced separately.

42. Discard and renew all thrust washers.

43. Differential housings with worn thrust washer

seatings must be replaced as a pair.

44. Examine differential case to crown wheel joint

face for burrs and damage which could lead to

crown wheel run-out when fitted.

ASSEMBLE

Differential

45. Fit differential lower wheel and thrust washer to

differential case. See illustration following

instruction 23.

46. Fit dished thrust washers.

47. Fit cross-shaft and pinions.

48. Fit differential upper wheel and thrust washer.

49. Fit differential upper case lining-up marks.

50. Secure assembly with bolts using Loctite

’Studlock’ grade CVX on threads and tighten

evenly and diametrically to

95 Nm (70 lbf/ft).

51. Fit crown wheel to differential casing. Use Loctite

’Studlock’ grade CVX on fixing bolt threads and

tighten to correct torque.

52. Press on differential roller bearing cones less

shim washers, using LRT-51-504, and leave to

one side until required for instruction 96.

53. Fit bearing cups to differential.

54. Fit differential unit and bearings to gear carrier

casing, and rotate unit to centralize bearings. Do

not fit bearing caps.