300Tdi Defender

REAR AXLE AND FINAL DRIVE

5

OVERHAUL

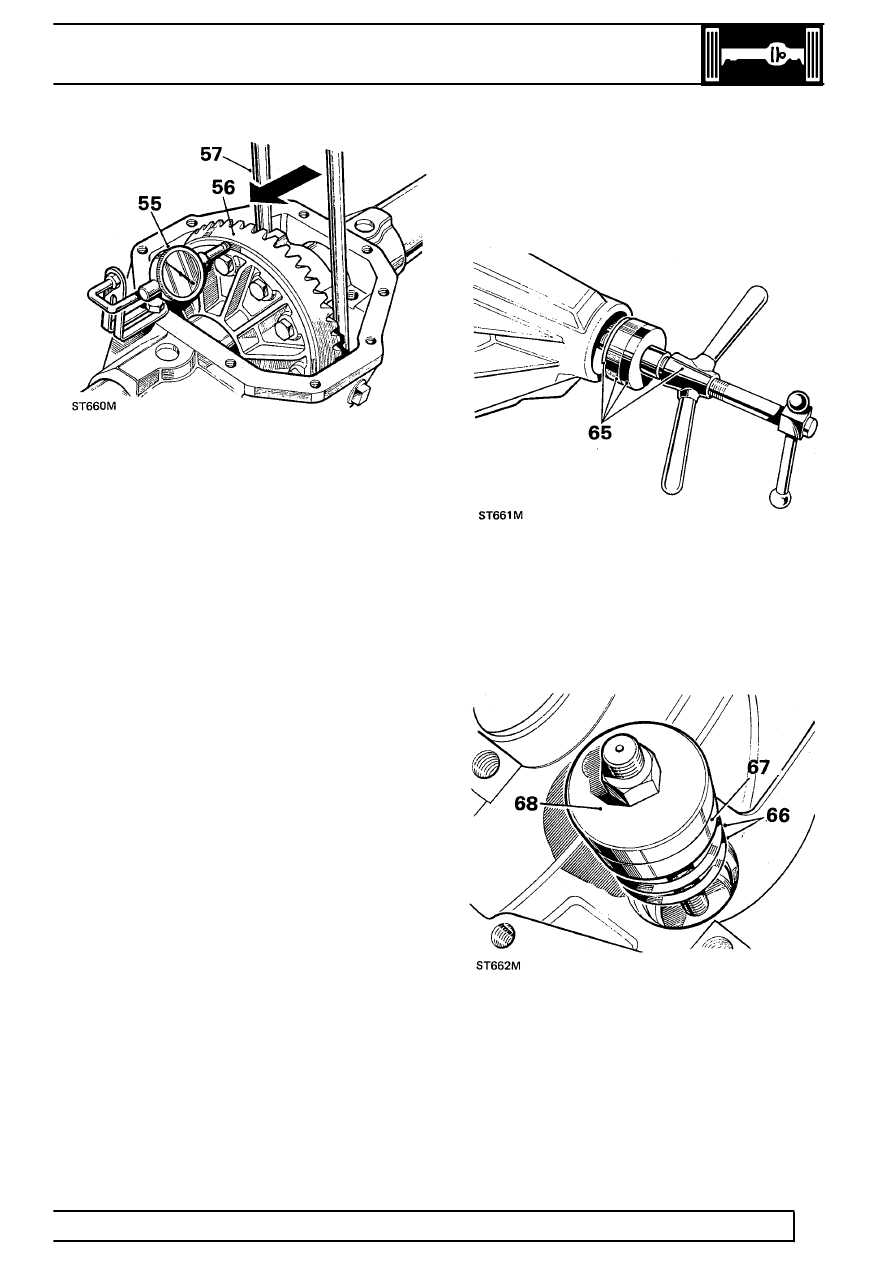

55. Position a suitable dial gauge indicator on casing

with stylus registering on back face of crown

wheel.

56. Rotate differential and check total indicated

run-out on crown wheel back face. This must not

exceed 0,05 mm. If run-out is excessive, check

mating faces for dirt and damage; if necessary,

select a new radial position for crown wheel.

When satisfactory, continue with following check.

Differential bearing adjustment

57. Insert two levers between casing and differential

unit at one side.

58. Move differential unit fully to one side of casing;

do not tilt unit.

59. Rotate differential unit to settle bearings,

continue to lever differential to side, then zero

dial gauge indicator.

60. Lever assembly fully to other side of casing,

rotate unit to settle bearings, then note total

indicator reading.

61. Add 0,127 mm, for bearing pre-load, to total

noted in preceding instruction. The sum is then

equal to nominal value of shims required for

differential bearings. Shims are available in

range 0,07 mm, 0,12 mm, 0,25 mm and 0,76

mm. Select total value of shims required.

62. Remove differential unit and bearings and place

aside. Do not fit shim washers until subsequent

’Differential backlash’ checks have been made,

instructions 96 to 102.

Fit drive pinion

63. Select shim washers of same thickness value as

those removed from under pinion inner cup,

instruction 35, and place ready for fitting.

64. Position outer bearing replacer LRT-51-505,

detail 2, and outer bearing cup on press

LRT-99-502.

65. Locate assembly into pinion housing nose.

66. Place selected shim washers on to inner bearing

cup seating.

67. Position inner bearing cup in casing.

68. Position inner bearing replacer LRT-51-505,

detail 1, onto LRT-99-502 and secure with fixing

nut.

69. Hold still centre screw and turn butterfly lever to

draw in bearing cups.