300Tdi Defender

51

REAR AXLE AND FINAL DRIVE

6

OVERHAUL

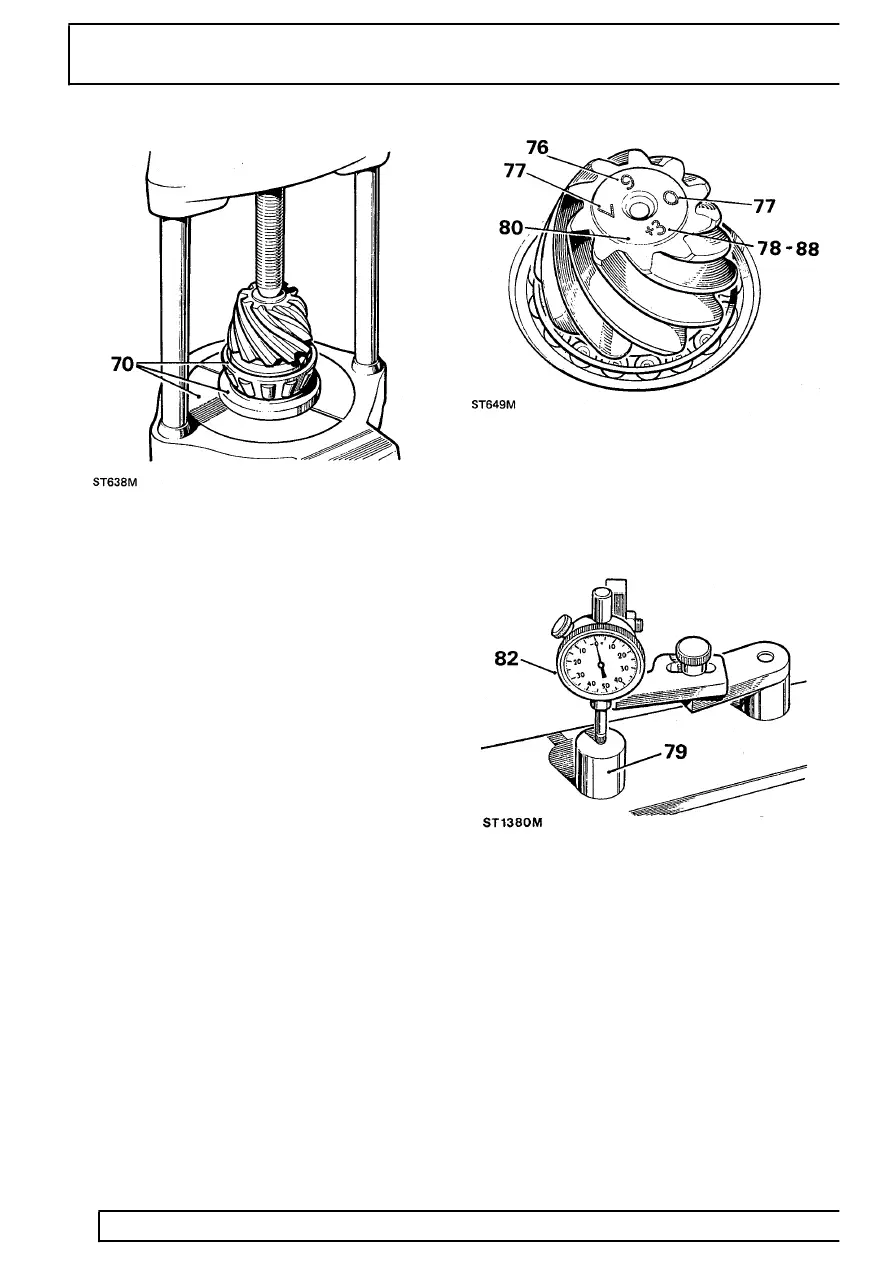

70. Press inner bearing cone onto drive pinion using,

LRT-51-502 details 1 and 2 and press

LRT-99-002.

71. Position pinion and bearing in casing; omit

collapsable spacer at this stage.

72. Fit outer bearing cone onto pinion.

73. Fit coupling flange and plain washer and loosely

fit flange nut.

74. Tighten coupling flange locknut to remove

end-float from pinion.

75. Rotate pinion to settle bearings and slowly

tighten flange locknut. Use a spring balance to

obtain a torque resistance of 11 Kgf/cm (18

lbf/in) to rotate pinion.

Drive pinion markings

76. Check that serial number marked on pinion end

face matches that marked on crown wheel.

77. The markings on end face adjacent to serial

number are of no significance during servicing.

78. The figure marked on end face opposite to serial

number indicates, in thousandths of an inch,

deviation from nominal required to correctly set

pinion. A pinion marked plus (+) must be set

below nominal, a minus (-) pinion must be set

above nominal. An unmarked pinion must be set

at nominal.

79. The nominal setting dimension is represented by

setting gauge block 18G191P or LRT-54-503,

which is referenced from pinion end face to

bottom radius of differential bearing bore. The

latter gauge is illustrated following instruction 85.

Drive pinion adjustment

80. Ensure that pinion end face is free of raised

burrs around etched markings.

81. Remove keep disc from magnetized base of dial

gauge tool 18G191.

82. Place dial gauge and setting gauge 18G191P or

LRT-54-503 on a flat surface and zero dial

gauge stylus on to setting gauge.