TD5 Defender

12

ENGINE

30

OVERHAUL

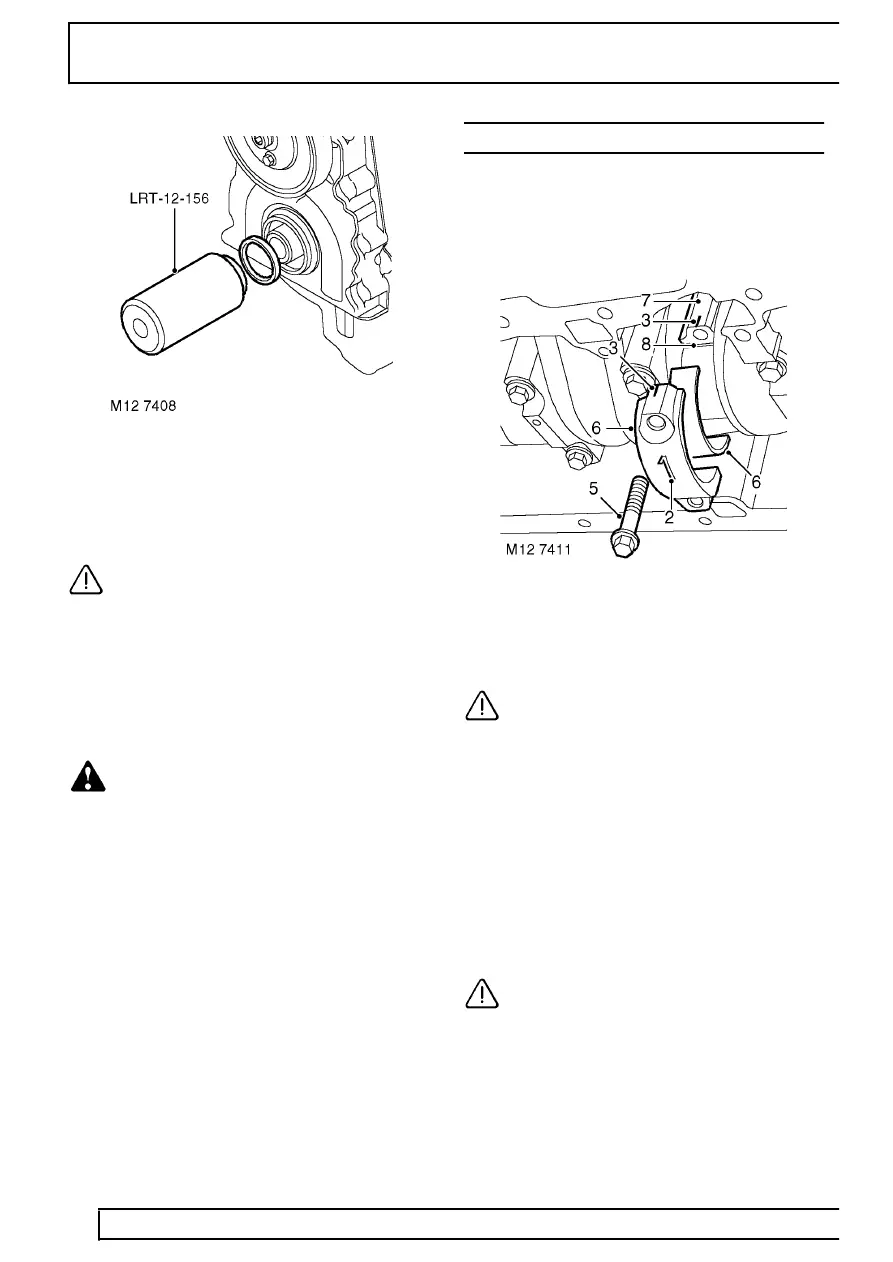

22. Fit oil seal guide, from seal kit, over end of

crankshaft.

23. Fit new oil seal into timing cover using

LRT-12-156.

CAUTION: Oil seal must be fitted dry.

24. Remove LRT-12-156 and oil seal guide.

25. Fit crankshaft pulley, fit crankshaft pulley bolt.

26. Fit LRT-51-003 to crankshaft pulley and secure

with 2 bolts.

27. Using assistance, restrain engine and using a

torque multiplier, tighten crankshaft bolt to 460

Nm (340 lbf.ft) .

WARNING: DUE TO THE HIGH TORQUE

LOADING REQUIRED, IT IS ESSENTIAL

THAT ENGINE IS ADEQUATELY

RESTRAINED.

28. Remove LRT-51-003.

29. Position damper to crankshaft pulley, fit 3 bolts

and tighten to 80 Nm (60 lbf.ft) .

30. Fit sump gasket. See this Section.

31. Fit cylinder head gasket. See this Section.

BEARINGS - CONNECTING RODS

Service repair no - 12.17.16.01

Remove

1. Remove oil pump. See this Section.

2. Mark cylinder reference number on each

connecting rod big-end bearing cap.

3. Make suitable alignment marks between each

big-end bearing cap and connecting rod.

CAUTION: Due to the ’fracture split’

method of manufacturing connecting rods

and bearing caps, incorrect fitting of cap

to connecting rod will damage mating faces and

necessitate replacement of connecting rod

assembly.

4. Rotate crankshaft clockwise until No. 1 big-end

is at BDC.

5. Remove and discard 2 bolts securing No. 1

big-end bearing cap.

6. Remove bearing cap, remove and discard

big-end bearing shell.

7. Push connecting rod up cylinder bore until rod is

clear of crankshaft journal.

CAUTION: Ensure that connecting rod

does not contact cylinder bore or oil squirt

jet and piston does not contact the valves

or EUI’s if the cylinder head is fitted.