TD5 Defender

12

ENGINE

2

REPAIR

13. Position camshaft in camshaft carrier.

14. Check end-float of camshaft using a DTI.

Camshaft end-float = 0.06 to 0.16 mm (0.002 to

0.006in).

15. Renew components as necessary to achieve

correct end-float.

CAUTION: Cylinder head and camshaft

carrier are machined together as an

assembly. If bearing surfaces in either

component are found to be damaged, complete

assembly must be replaced.

NOTE: The procedure for checking

camshaft bearing clearances is covered in

Td5 Engine Overhaul section - Cylinder

head - overhaul.

Refit

16. Using a suitable cleaning solvent, clean mating

faces of cylinder head and camshaft carrier.

17. Blow out all oilways and waterways.

18. Ensure threaded holes in cylinder head and

camshaft carrier are clean and dry.

CAUTION: Support each end of the

cylinder head on blocks of wood. With

camshaft carrier bolted down some valves

and the injector nozzles will protrude from the

face of cylinder head.

19. Fit new adjusting screws fully into rocker arms.

Fit new lock nuts to screws but do tighten.

CAUTION: Ensure screws are correct for

type of rocker arms fitted. Replacement

screws for Engine Serial No. Prefixes 15P

to 19P have a centre punch mark adjacent to the

adjusting screw slot. These screws are not

interchangeable with those fitted to Engine Serial

No. Prefixes 10P to 14P.

20. Lubricate cams and bearing journals on

camshaft, cylinder head and camshaft carrier

with clean engine oil.

21. Position camshaft in cylinder head with the

timing pin hole in the vertical position.

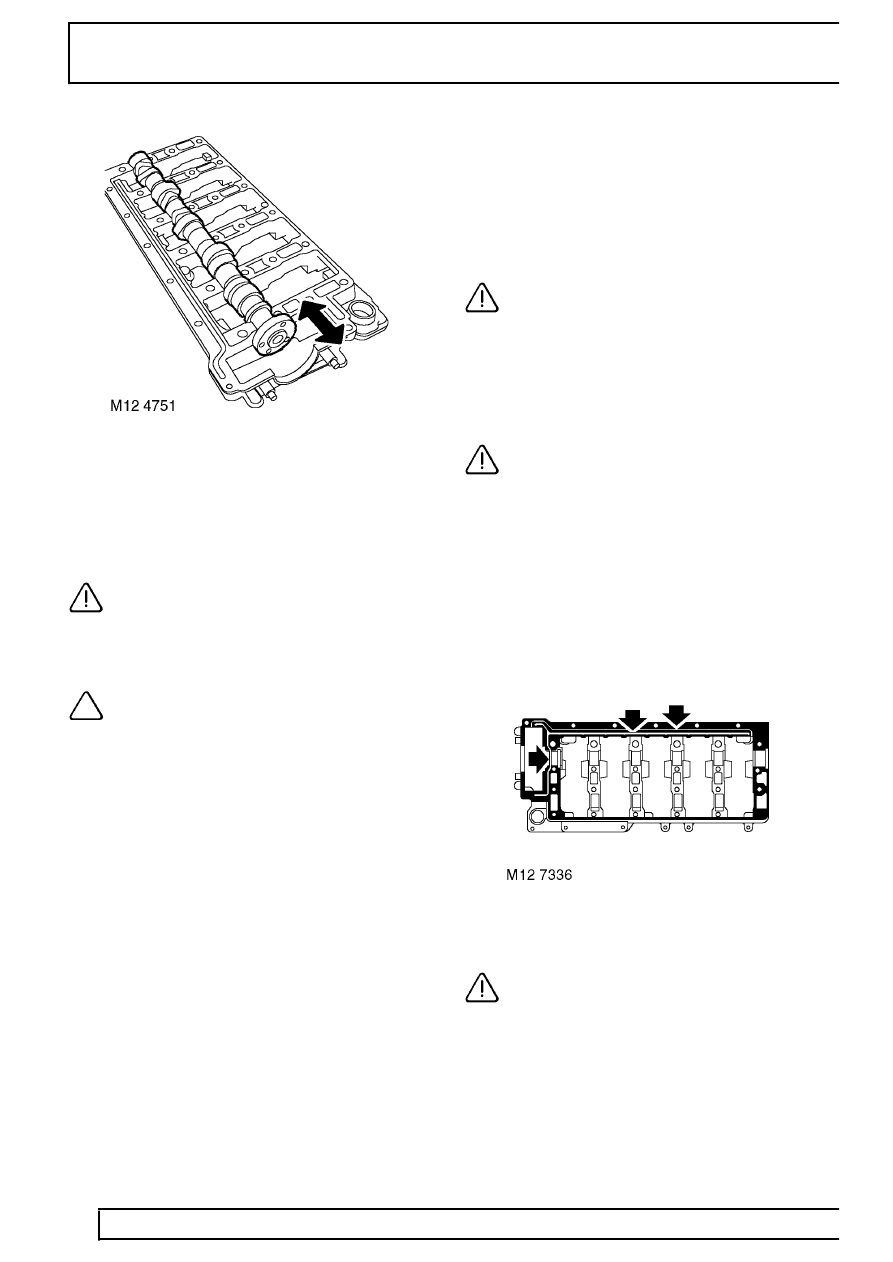

22. Apply an even film of sealant, Part No. STC

4600 to camshaft carrier face as shown and

spread to an even film using a roller.

CAUTION: Ensure sealant does not block

oilways (arrowed) or contaminate

camshaft bearings. Assembly and bolt

tightening must be completed within 20 minutes

of applying sealant.

23. Fit camshaft carrier ensuring that it is correctly

located on dowels.

24. Fit and lightly tighten camshaft carrier bolts.